Your advice please.

I am making a downstairs shower room with a low profile quadrant tray, in what was previously a typical 1930's kitchen - the original concrete floor stepped down 120mm from the rest of the house.

But that floor has now been built up with joists and 22mm plywood to match the ground floor level.

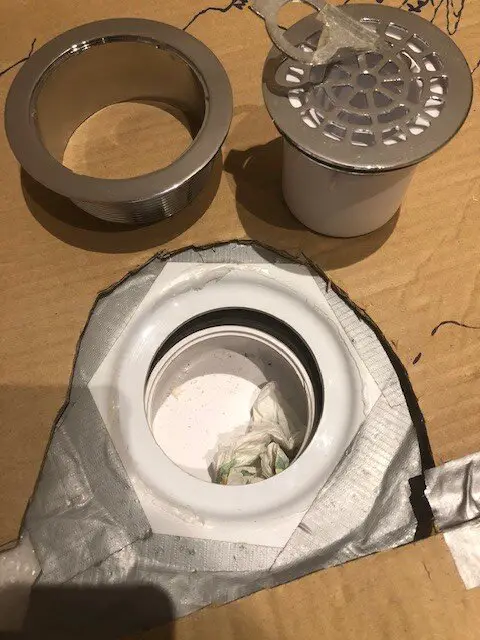

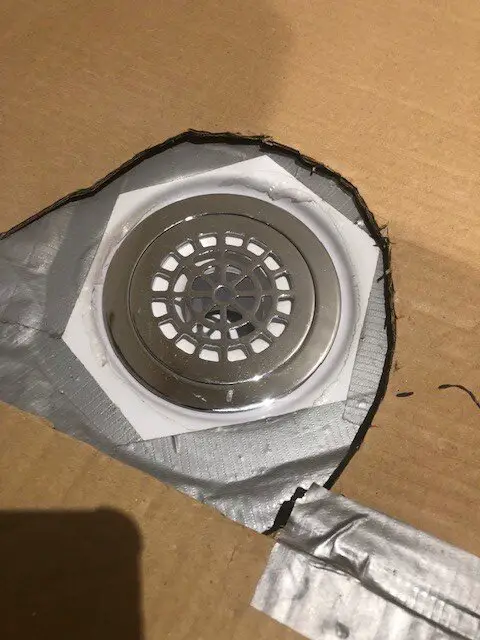

The 40mm solvent welded shower waste runs in that void, joining the tray at the McAlpine ST90CPB-P-70 trap - but the last 2 joints are the trap's own compression connectors with their sealing washers - that part is my concern!

>> See photos

My Concern >> Once the tray is lowered, fastened and the trap sealed to the tray from above, that will be permanent with no way of ever knowing if any leaks should occur over time?

But this is non-pressure waste for an occasional used shower, and I am using the McAlpine trap which is a quality recommended item.

However, I'm still concerned for those hidden compression joints in particular.

> A couple of plumbers have told me to just seal it up with low-modulus or CT1 sealant on everything and it will be fine !.

> I do not want to build up a 3"/ 75mm raised platform for the shower tray to sit on. I know that could give access, but I feel it looks ugly and defeats the object of a low shower ingress.

And in that case I still wouldn't be aware of any leaking, raised or not. And unless it had an access panel on the side of the platform that could be opened for inspection periodically, I wouldn't know if it was leaking. I don't see much benefit going that route.

Q? > But am I worrying about this unnecessarily? Should I follow the advice to do a belt and braces sealant job and just close it up?

And if this pipework was all buried in concrete, which is quite usual, it would be solvent weld the whole way, so would we then worry about this?

Q?> Or should I do something about this and either:-

1> Somehow make the whole waste run including the trap in solvent weld? But that would perhaps mean using a different trap without these compression joints?

Or ...

2> Look at some kind of small floor access trap that can take the tiles and just leaves a neat couple of stainless bolts?

Your help and advice is welcomed.

Thanks very much

I am making a downstairs shower room with a low profile quadrant tray, in what was previously a typical 1930's kitchen - the original concrete floor stepped down 120mm from the rest of the house.

But that floor has now been built up with joists and 22mm plywood to match the ground floor level.

The 40mm solvent welded shower waste runs in that void, joining the tray at the McAlpine ST90CPB-P-70 trap - but the last 2 joints are the trap's own compression connectors with their sealing washers - that part is my concern!

>> See photos

My Concern >> Once the tray is lowered, fastened and the trap sealed to the tray from above, that will be permanent with no way of ever knowing if any leaks should occur over time?

But this is non-pressure waste for an occasional used shower, and I am using the McAlpine trap which is a quality recommended item.

However, I'm still concerned for those hidden compression joints in particular.

> A couple of plumbers have told me to just seal it up with low-modulus or CT1 sealant on everything and it will be fine !.

> I do not want to build up a 3"/ 75mm raised platform for the shower tray to sit on. I know that could give access, but I feel it looks ugly and defeats the object of a low shower ingress.

And in that case I still wouldn't be aware of any leaking, raised or not. And unless it had an access panel on the side of the platform that could be opened for inspection periodically, I wouldn't know if it was leaking. I don't see much benefit going that route.

Q? > But am I worrying about this unnecessarily? Should I follow the advice to do a belt and braces sealant job and just close it up?

And if this pipework was all buried in concrete, which is quite usual, it would be solvent weld the whole way, so would we then worry about this?

Q?> Or should I do something about this and either:-

1> Somehow make the whole waste run including the trap in solvent weld? But that would perhaps mean using a different trap without these compression joints?

Or ...

2> Look at some kind of small floor access trap that can take the tiles and just leaves a neat couple of stainless bolts?

Your help and advice is welcomed.

Thanks very much

Last edited: