- Joined

- 10 Nov 2024

- Messages

- 19

- Reaction score

- 1

- Country

Hi all

I have a standard Y plan heating system with a Potterton Suprima 50 in the kitchen, 3-port valve, Myson Compact CP53 pump, and hot water tank in the airing cupboard, then an F&E tank in the loft; with a combined feed and vent.

The heating system is simple and generally performs well, with all rads getting hot and Hive suggests the house heats up quickly. Considering its age, it does seem fairly efficient.

However, ever since we moved in we have had a “whooshing” and thudding noise occur that is quite loud every time the CH pump starts up. After about 30 secs to 1 minute the air noise has completely stopped and the system is fairly quiet and normal.

For ages I have ignored this on the basis the system was working fine but the noise is now waking up our 2yo as her bedroom is opposite the airing cupboard.

I have stood near the pump and turned the heating on and the noise seems to be occurring above the pump (the pump direction is downwards towards the 3-port valve) and is therefore seemingly sucking air in from above.

I am confused by this as my understanding of a combined F&V is that air cannot (easily) get in as the water level is above the combined F&V pipe.

Tonight I have sat in the loft and felt the pipes leading up to the F&E tank get warm but nothing drastic, and the final “rise” up to the F&E tank stays cold. The water level in the F&E tank doesn’t seem to change.

I have attached pictures of the condition of the F&E water, the combined F&V pipe, the pump, and the start of the combined F&V pipe leading up to the F&E tank.

Is my assessment of an air lock correct and if so, what is the best way forward please?

Any help much appreciated!

Cheers

Mike

I have a standard Y plan heating system with a Potterton Suprima 50 in the kitchen, 3-port valve, Myson Compact CP53 pump, and hot water tank in the airing cupboard, then an F&E tank in the loft; with a combined feed and vent.

The heating system is simple and generally performs well, with all rads getting hot and Hive suggests the house heats up quickly. Considering its age, it does seem fairly efficient.

However, ever since we moved in we have had a “whooshing” and thudding noise occur that is quite loud every time the CH pump starts up. After about 30 secs to 1 minute the air noise has completely stopped and the system is fairly quiet and normal.

For ages I have ignored this on the basis the system was working fine but the noise is now waking up our 2yo as her bedroom is opposite the airing cupboard.

I have stood near the pump and turned the heating on and the noise seems to be occurring above the pump (the pump direction is downwards towards the 3-port valve) and is therefore seemingly sucking air in from above.

I am confused by this as my understanding of a combined F&V is that air cannot (easily) get in as the water level is above the combined F&V pipe.

Tonight I have sat in the loft and felt the pipes leading up to the F&E tank get warm but nothing drastic, and the final “rise” up to the F&E tank stays cold. The water level in the F&E tank doesn’t seem to change.

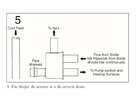

I have attached pictures of the condition of the F&E water, the combined F&V pipe, the pump, and the start of the combined F&V pipe leading up to the F&E tank.

Is my assessment of an air lock correct and if so, what is the best way forward please?

Any help much appreciated!

Cheers

Mike