Hi, Guys,

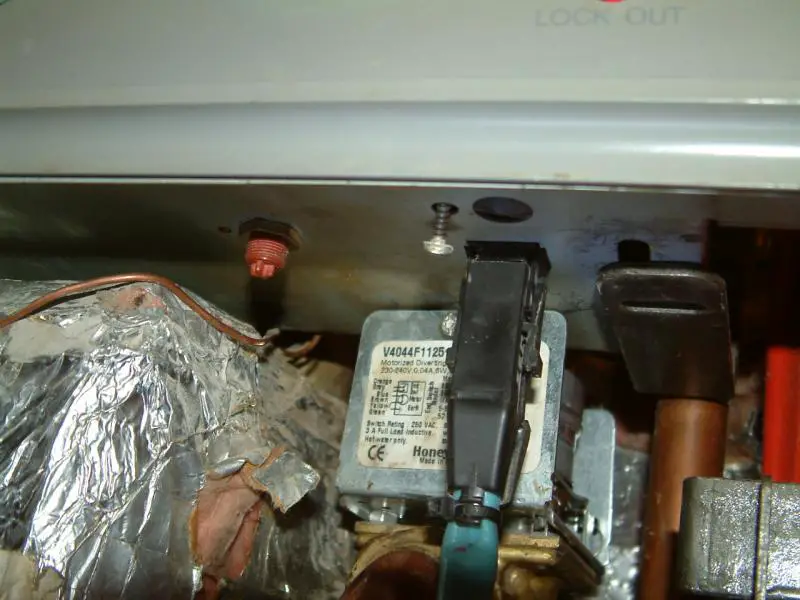

I hope someone can help PLEASE, I have a Worcester 15/19 Heatslave with no HW or CH water, the other day I had a load noise coming from the water pump so I changed it, but now I have no HW or CH water, the pump is the correct way up & the electrics are correct, the diverter valve was changed about 18 months ago & since has run ok, today I isolated the boiler & drained it down, while empty I set the expansion vessel pressure to .5 bar & refilled it slowly via the filler loop, the diverter valve was set at manual & all bleed valves open, I restarted the boiler it will runs fine for about 6 or 7 mins then stop, it will not restart until it cools down, I removed the powerhead off the diverter valve, I checked the motor on it the reading is 2290 ohms’, I get a open & close circuit when the when I move the lever between manual & auto, I’m at my wits end as to what it can be, can someone HELP me PLEASE.

Living in Hope

Kelvin

I hope someone can help PLEASE, I have a Worcester 15/19 Heatslave with no HW or CH water, the other day I had a load noise coming from the water pump so I changed it, but now I have no HW or CH water, the pump is the correct way up & the electrics are correct, the diverter valve was changed about 18 months ago & since has run ok, today I isolated the boiler & drained it down, while empty I set the expansion vessel pressure to .5 bar & refilled it slowly via the filler loop, the diverter valve was set at manual & all bleed valves open, I restarted the boiler it will runs fine for about 6 or 7 mins then stop, it will not restart until it cools down, I removed the powerhead off the diverter valve, I checked the motor on it the reading is 2290 ohms’, I get a open & close circuit when the when I move the lever between manual & auto, I’m at my wits end as to what it can be, can someone HELP me PLEASE.

Living in Hope

Kelvin