First, you are right .There is additional gear - in fact a VR61 and VR81 (in upstairs zone).

The VR61 is near the boiler and zone valves . As opposed to the VR65 it allows separate control of 2 CH zones, and a single DHW zone.

Thanks for drawing my attention to the VR61; I wasn't aware of it.

My understanding of radiator output power is based on fairly standard figures of 75C flow and 65C return thus giving a notional mean of 60C.

I think you intended to write "70C" mean!

The next assumption is the room temp of 20C hence the Delta 50 banded about. ie difference between rad mean and room temp. The so called 75,65,20 system for quoting output rates. these are rarely perfectly accurate, as there is no such real thing as a mean radiator plate temperature, but it is a start.

They are accurate when the rad outputs are measured under the controlled conditions laid down in BS EN442. "Mean" rad temperatures is a simplification as it's the actual flow and return temperatures which are significant. A "1000W" rad will give out 980W when the temperatures are 80/60 and 930W at temperatures of 90/50.

If the room is colder we will have a larger delta T and higher outputs. likewise outputs differ if radiator means are changed, as they always are by eg TRVs or boiler flow temp, pump flow etc. This relationship is not linear and I have a delta T table of correction factors that Agile will know all about. I rarely use it!

I hope I have this correct?

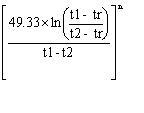

Yes that's correct. The table of correction factors is also a simplification as it makes assumptions. The formula similar to this:

It's not 100% correct as the constant should be 49.83. T1 is the flow temp, T2 Return Temp and Tr is Room temp. n is a constant which depends on size and type of rad; it's about 1.3.You divide the nominal output by the calculated value to give the actual output

I reasoned I could run the radiators cooler, and obtain better and lower average return temps. While reasonable condensing will occur at 50 or even 55*C returns , benefits are actually considerably enhanced at even lower return temps.

The range of outside temperatures you want to cater for is important If you are running with a flow of 70C when it is -5 outside, what flow temp will you need when it is 15 outside and can the boiler provide this. Also can the boiler modulate low enough.

I am getting surer and surer I will probably need a bigger but still modulating circulation pump. I don't think the installer took the very high boiler flow resistance and length of pipe runs into account.

Regrettably that is probably true. Most installers just do not realize the effect modern heat exchangers have.

I did some calculations on my system and found that the index circuit is 1.61m with the boiler resistance of 0.71m. The new boiler I am proposing to install has a resistance of 4m, so the index circuit immediately increases to 4.9m. At present I have a UPS 15-50. The Grundfos recommended pump for the new boiler is a Magna 25-60. Fortunately, like you my house is well insulated and the rads on average 90% oversized. So I can easily run the system with a 20C differential, which almost halves the flow rate and reduced the head considerably..

Do you think it will be feasible to run boiler flow below 70C?

Don't see why not. There may be the odd day when the outside temperature is so low that the boiler has to run at a higher temperature. As you have weather compensation you will be able to play around with the curve to get the optimum settings.

Also could you comment on my solenoid valve bypass scheme?!!

I can see what you are trying to do, but can't work out how it would be connected. The solenoid valve only needs to open if

all zone valves are closed. A relay could do this, but you need to make sure that there is no back-feed between the zone valves.