I presume soIs this actually a serious discussion? I can't tell. Are we just talking about a standard plumbing Flexi pipe?

Kind Regards, John

I presume soIs this actually a serious discussion? I can't tell. Are we just talking about a standard plumbing Flexi pipe?

That isn't correct.According to Wiki ROI regs banned uninsulated CPCs in 2013

Although plenty of people have done such things, it was never a requirement.years ago it was a requirement to earth all pipes and sinks and tubs,

I don't now any secrets and presume it guards against abrasion - oh, and it looks nice

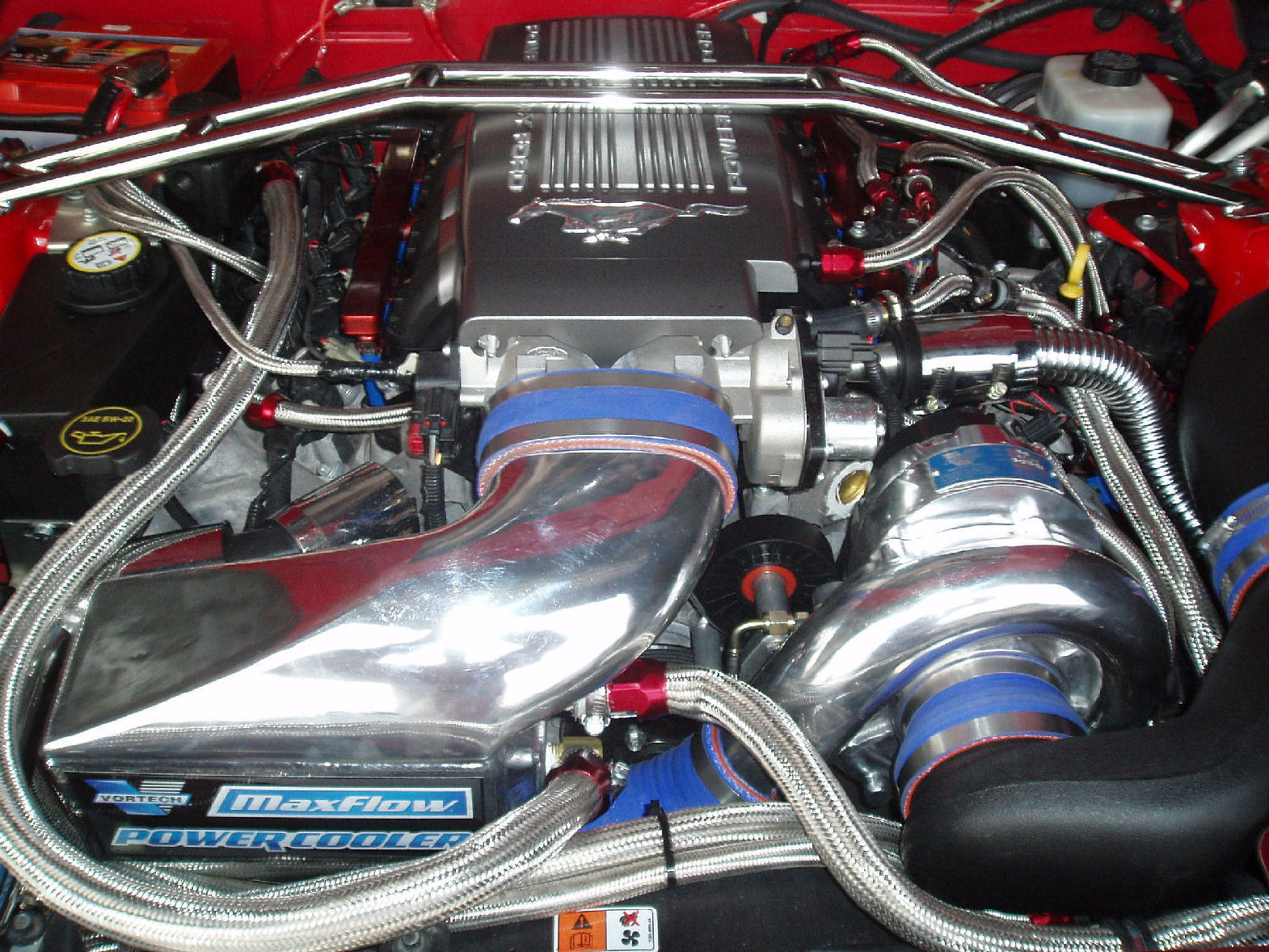

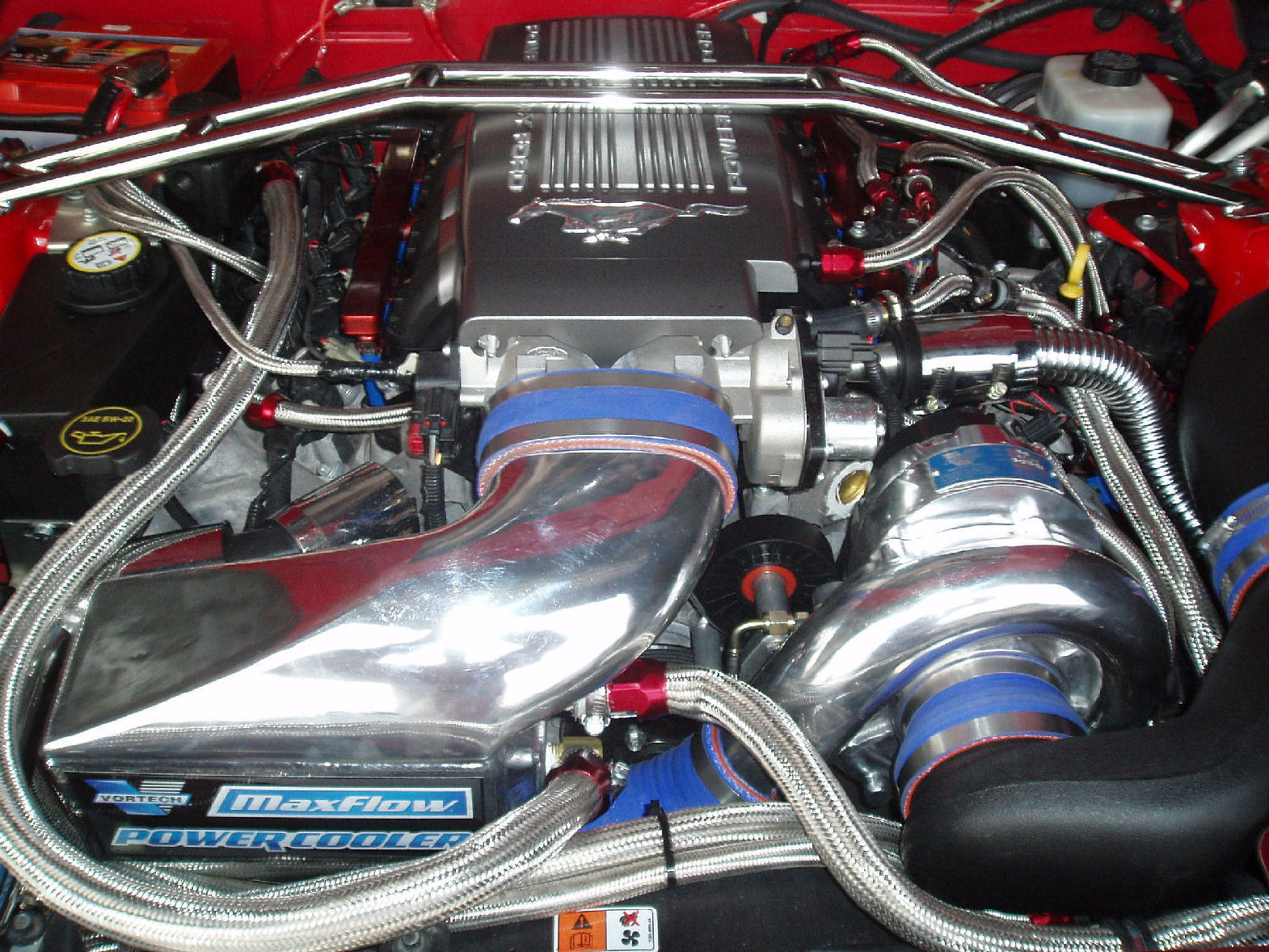

Because you would then end up with a lower pressure (at the desired injection temperature) than you wanted. As you have implied, it's all down to the laws of Physics..... so why not use a smaller booster (turbo) and not then having to use an intercooler.

... except that, unless in conduit etc., regs do not allow a single-sinsulated live conductor (particularly when the sheathing of T+E may not even be 'rated as insulation').However twin and earth with no id sleeving on the bare copper there is nothing to say that cable can't be used for other than earth bonding ...

In terms of BS7671, that's only true of singles. There is nothing in BS7671 which says that over-sleeving of G/Y is not permitted in multi-core cables (such as T+E), even if many/most of us would probably not regard it as a very desirable practice.... but where it has the yellow/green covering then not permitted to over sleeve.

You're welcome. It's really just a case of the temperature rise being an unavoidable (and largely unwanted) 'side-effect' of the compressing, such that one has to 'undo' that side effect, returning one to the situation that one would have had if that 'side effect' had not existed.I get it now John, thanks, sorry to drag you into this. But yes fully understands it now. I thought there must be a catch in this somewhere, otherwise why would anyone want to hang a great big shining aluminium Intercooler in front of their wagon and blocking its radiator!

Exactly.I think I have understood it now, so what you are saying is when Turbo spins, it compresses the incoming air let us say to our intended target value of 3 bars, but as air starts to get compressed it also heats up, in doing so its pressure increases further so instead of getting 3 bars, it may have gone up in pressure to say 4 bars, so we now cool it down by passing it through an intercooler where the temperature drops down and and we are back in business at 3 bars what we intended. Got it I think.

Again, exactly. I was talking about an adiabatic compression (i.e. a process that happens so quickly that there is no time for any heat to be lost) - which is essentially what will be happening in a turbo-charger. As you say, that's why one has to use a cooler rather than wait for it to cool down itself - if one tried the latter, the engine would probably only be able to do one stroke every hour or so (hardly a 'go faster' techniqueOf course if you look at it from another point, heat is produced when air ( or any gas) is compressed, so if we were to trap this compressed air in a canister, initially it would get heated up and then lose its temperature, and eventually the canister cools down to ambient or surrounding temperature, but still has that compressed air in it. Intercooler helps cool air quickly so that it can be used immediately in cylinders of car engine, whereas a canister can take all its time to cool off slowly.

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Are you a trade or supplier? You can create your listing free at DIYnot Local