It's a diy job.

Just a general comment, how reliable is the plumber who upgraded your system? There is a lot of PTFE tape showing on the compression fittings that is not required, jointing compound perhaps but not tape. ...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hot water temp is 40 Degrees - Ideal Mexico 2 Boiler

- Thread starter JackK

- Start date

Sponsored Links

This system worked before yes - I think if I have to slcken the nut I cant do that.It's a diy job

The plumber came highly reccoemended and is 70 years old - The PTFE is maybe excessive but apart from that its ok no?

The gate valve is fully open yes I am sureThis system worked before yes - I think if I have to slcken the nut I cant do that.

The plumber came highly reccoemended and is 70 years old - The PTFE is maybe excessive but apart from that its ok no?

The old copper cylinder was leaking - Now its been replaced

This system worked before yes - I think if I have to slcken the nut I cant do that.

The plumber came highly reccoemended and is 70 years old - The PTFE is maybe excessive but apart from that its ok no?

If it worked before, and doesn't work after the new cylinder was installed, then surely you ought to call your plumber back to fix it..

Sponsored Links

I am having another plumber attend tomorrow - I want to understand the fuss about the flow pipe being slightly high

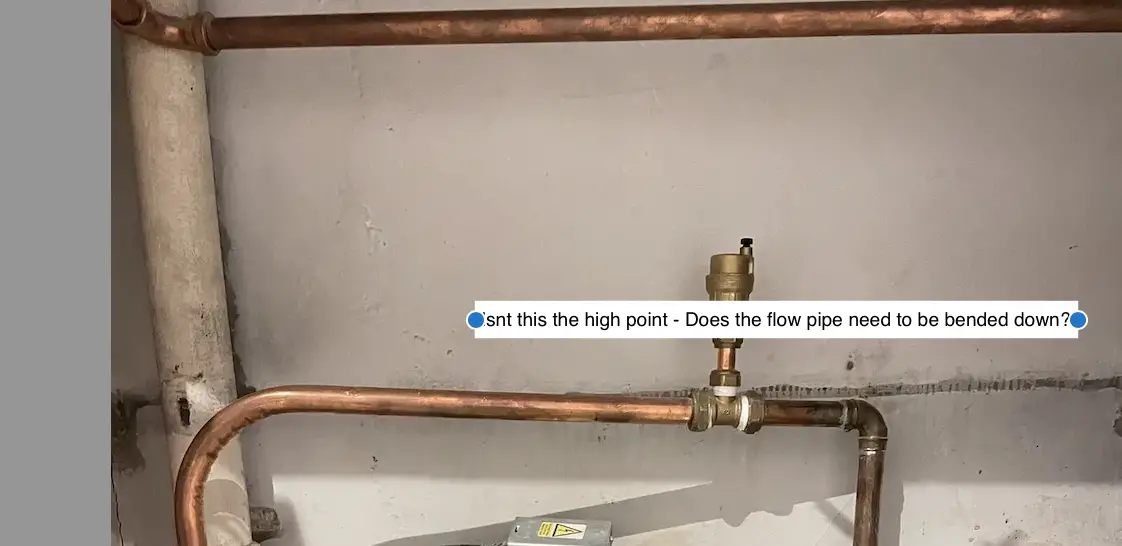

Isnt the highest point where the air vent is? If so any air will come out of the airvent which is highest point on the run - When the boiler is working the flow pipe is red hot but the return is only lukewarm which indicates an airlock or gravity not helping getting the water into the cylinder

Which one of these two is your best guess - Would rather not have to remove the pipe and shorten it if I can avoid it

Isnt the highest point where the air vent is? If so any air will come out of the airvent which is highest point on the run - When the boiler is working the flow pipe is red hot but the return is only lukewarm which indicates an airlock or gravity not helping getting the water into the cylinder

Which one of these two is your best guess - Would rather not have to remove the pipe and shorten it if I can avoid it

Try putting a level on the 'horizontal ' pipe!

I know the horizontal pipe is higher at the left - My point was that the air vent is higher then even the highest point of the horizontal pipe so no air should collect in there?Try putting a level on the 'horizontal ' pipe!

I also worry that the flow is being restricted with all these bends which will explain why the cylinder never gets very hot (even with the boiler on max temp) and the return is only lukewarm

Honestly the quality of work from builders these days levaes a lot to be desired even those who are plumbers and gas engineers !

It's simple your air vent is not your highest point!

Air is collecting on that bend.

Air is collecting on that bend.

Im so sorry - I just dont understand this - The air vent is higher - The water will collect at the top of the airvent before releasing airIt's simple your air vent is not your highest point!

Air is collecting on that bend.

I really dont want to pay 150 to have a pipe rebent if it wont solve my issue - Please help me to understand your suggestion

Thank you so much

Im so sorry - I just dont understand this - The air vent is higher - The water will collect at the top of the airvent before releasing air

I really dont want to pay 150 to have a pipe rebent if it wont solve my issue - Please help me to understand your suggestion

Thank you so much

The body of the air vent, is higher. Problem is, that the connection between pipe and air vent [1] - is not the highest point, the bend on the left is higher. Thus, air will be able to collect at the bend, and in at least part of that horizontal pipe.

If you have one, hold a long level at point [1]. Any pipe work which then shows above you level, can collect an airlock and restrict the flow.

This thread is on page three.The boiler thermostat is operated by a dial at the front of the boiler - It is set to 3 at the moment - I can turn it up to 4 or 5 but I wanted to keep the heating on for longer and at a lower temperature rather than a high temp for short period

I have only one motorised valve which I have set into manual mode

It is time the OP listened and acted on advice the pros have given. We do this type of work every day. Advice given on page one seems to have fallen on deaf ears.

If system is gravity hot water (has that been verified?), circulation to cylinder is going to be poor bearing in mind the flow is 22 ( gravity primaries are normally 28), return is 15mm.

The blockage is the flow pipe itself. You CANNOT Have that shape of pipe. For gravity circulation to work, one has to imagine a circuit where hot water rises and cold sinks

Furthermore, do you know if this cylinder is suitable for gravity circulation?

What is the 22mm motorised valve connected to and why is it not operational

Boiler thermostat needs to be set higher.

How long is the system run to heat water.

is heating and hot water run together? Has water alone been tried?

BTW, why is X400 in the system; system will need flushed several times to remove system debris that thE chemical has lifted

Thank you - I really try and understand my systemThis thread is on page three.

It is time the OP listened and acted on advice the pros have given. We do this type of work every day. Advice given on page one seems to have fallen on deaf ears.

If system is gravity hot water (has that been verified?), circulation to cylinder is going to be poor bearing in mind the flow is 22 ( gravity primaries are normally 28), return is 15mm.

The blockage is the flow pipe itself. You CANNOT Have that shape of pipe. For gravity circulation to work, one has to imagine a circuit where hot water rises and cold sinks

Furthermore, do you know if this cylinder is suitable for gravity circulation?

What is the 22mm motorised valve connected to and why is it not operational

Boiler thermostat needs to be set higher.

How long is the system run to heat water.

is heating and hot water run together? Has water alone been tried?

BTW, why is X400 in the system; system will need flushed several times to remove system debris that thE chemical has lifted

1) I have a pumped flow pipe which tees off for hot water cylinder and then gravity returns back to the boiler - I believe this is therefore "fully pumped" ?

2) The cylinder is "suitable for only fully pumped" system

3) System is running for three or four hours and still water in cylinder is 40 degrees max

4) Heating and hot water run together - My setup does not allow hot water only

5) Boiler is set to max temp output and is a gas guzzler - Ideal Mexico 2 125 BED

6) I flushed out X400 after 4 weeks yesterday to remove all the sludge - Water brown and dirty - Magnaclean not caught any big bits of rubbish and a bit of magnatite on magnet

7) Two port valve set to manual as I wanted to avoid the thermostat on cylinder as not yet properly installed - That wont make a difference

I think the takeaway is : Flow pipe needs to be redone in 28mm without a loop yes? The cylinder only accepts 22mm inwards so it will be reduced before it goes into cylinder - Is that going to make a difference?

I dont know if this new cylinder ever worked : ( - Before I had 2 inch steel pipe work to cylinder flow and that was good but cylinder leaked so was replaced with this green one

For that colour of water, suspect pump over taking place so flow or return may well be blocked someplaceWater brown and dirty

Cannot see why not. How many motorised valves do you have.Heating and hot water run together - My setup does not allow hot water only

What programmer?

Good controls would keep that in check. Fitted high end controls for a customer with same boiler, her bills have come down while maintaining comfortonly

5) Boiler is set to max temp output and is a gas guzzler - Ideal Mexico 2 125 BED

.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 2

- Views

- 2K

- Replies

- 16

- Views

- 7K

- Replies

- 14

- Views

- 2K