You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kill switch doesnt kill engine

- Thread starter ipbr21054

- Start date

Could you re write that so someone getting on in years can understand pleaseThere is continuity to wart but I can’t get to the end of the coil wire as could split the engine case even with all bolts undone of did I forget something.

phone changed it.

There is continuity to earth

So now I need to check the small wire that comes from the coil but as it goes through the casing and having tried before to split the casing I’m now stuck.

So did I forget something as to why I’m unable to split the item in two so I can then see the coil etc.

There is continuity to earth

So now I need to check the small wire that comes from the coil but as it goes through the casing and having tried before to split the casing I’m now stuck.

So did I forget something as to why I’m unable to split the item in two so I can then see the coil etc.

phone changed it.

There is continuity to earth

So now I need to check the small wire that comes from the coil but as it goes through the casing and having tried before to split the casing I’m now stuck.

So did I forget something as to why I’m unable to split the item in two so I can then see the coil etc.

I was trying to save you splitting in post#3 ...which ill repeat.phone changed it.

There is continuity to earth

So now I need to check the small wire that comes from the coil but as it goes through the casing and having tried before to split the casing I’m now stuck.

So did I forget something as to why I’m unable to split the item in two so I can then see the coil etc.

If you read the resistance between the switch end of kill wire to engine ground it should test continuity of it without getting to the coil end of it.

If it reads low ohms the wire is good but if it reads m ohms youd better get splitting

edit if you get high reading, try testing just before the wire goes through the casing by slightly bearing the wire or shoving a pin in which will test the external length

What about post #7

Before you split you could eliminate everything other than a break in the kill wire by starting the machine then touch the kill wire to engine to see if it keeps running or not

Sorry i didnt see post 7.

The way its wired up is as follows.

Wire with ring connector to underside of body.

This wire goes to one side of the switch.

The other side of the switch goes down the side of the body then through the body.

So i need to check inside the case now.

Last time i had removed all the allen bolts through the lower casing.

I can see the blades in grease where they meet together.

I was unable to go any further than this.

can you advise please then i can get on it thanks.

If you need photos etc please ask.

The way its wired up is as follows.

Wire with ring connector to underside of body.

This wire goes to one side of the switch.

The other side of the switch goes down the side of the body then through the body.

So i need to check inside the case now.

Last time i had removed all the allen bolts through the lower casing.

I can see the blades in grease where they meet together.

I was unable to go any further than this.

can you advise please then i can get on it thanks.

If you need photos etc please ask.

go back to post #22 first

Just tried that but keeps running.

Used choke to kill it.

I'm sure you know, but just to double check...

You did bare the end of the wire and connect it directly onto the engine casing with no paint on it?

Try giving the wire a tug, does it feel solid? If it feels as if it is stretching at all, it could be snapped inside the insulation.

I left one end connected to the body.

Other end has a bare spade terminal so i touched the body with the terminal.

I also used the multimeter to check for continuity & buzzer sounds so I believe the wire is then fine.

I can pull it slightly but then it stops.

There is a solid bung that it passes through in the casing so not sure if wire is off inside casing and the bung is then the brick wall as to speak.

I spiked the wire just before the bung and there is continuity so that means wire from body through the switch & down to the bung is fine.

Leads me to believe i need to now split it.

Before i re mote trimmer handle.

Lower plate on say gearbox.

Now i see where the 3 blades rotatae etc within the grease.

Removed all allen bolts through the casing.

Then had to stop.

Other end has a bare spade terminal so i touched the body with the terminal.

I also used the multimeter to check for continuity & buzzer sounds so I believe the wire is then fine.

I can pull it slightly but then it stops.

There is a solid bung that it passes through in the casing so not sure if wire is off inside casing and the bung is then the brick wall as to speak.

I spiked the wire just before the bung and there is continuity so that means wire from body through the switch & down to the bung is fine.

Leads me to believe i need to now split it.

Before i re mote trimmer handle.

Lower plate on say gearbox.

Now i see where the 3 blades rotatae etc within the grease.

Removed all allen bolts through the casing.

Then had to stop.

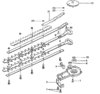

This shouldn't be a difficult job, it's only checking continuity over a couple of wires. Have a look online for an exploded diagram of your trimmer, then you can see how everything goes together/comes apart.

Can we have a pic of the errant wire please? The wire is usually single strand and varnished but it's easy enough to extend- if that's whats needed.

John

John

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 8

- Views

- 1K