But you don't need a large capacity cylinder with PDHW, that's one of the joys of it. Also, if you set 60ºC flow temperature for heating the water it'll take forever. Wants to be around 80-85 for best reheat times, which allows you to get back to heating the radiators more quickly. Trust me, I've installed a great number of systems just like this, I do know what I'm talking aboutCant agree with that. A large capacity cylinder that's been run cold could take longer than that to recover and if the CH is off for 30+ mins, with people coming and going then the air temp could drop significantly.

The radiators wouldn't get too hot if the set temp was say 60 deg for the HW

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Remote control of boiler flow temperature?

- Thread starter JonathanM

- Start date

Sponsored Links

Modulation is 5:1, better than some others. But not wanting faults, even with long warranty. Price appeals though! Quote of £1900 for H24 changeover from 32 year old Baxi.It possibly can, but you don't want a Logic, too many known faults and the modulation is terrible

I think you recommended Intergas Xclusive above? I can only find combi version on the website, not system. Am I looking at the right model?

D

Deleted member 267285

Some Intergas boilers can be changed in parameters, such as the eco rf, not sure one th xclusive.

You mean change to run as a system boiler?Some Intergas boilers can be changed in parameters, such as the eco rf, not sure one th xclusive.

Sponsored Links

D

Deleted member 267285

Yes, but @muggles knows more about this pdhw than me, so might be best he answers the query, as it might only work with a Combi.You mean change to run as a system boiler?

Yeah, fair enough and not disputing that a system setup with those components and set up like that could be suitable, as you are obviously well experienced with them.But you don't need a large capacity cylinder with PDHW, that's one of the joys of it. Also, if you set 60ºC flow temperature for heating the water it'll take forever. Wants to be around 80-85 for best reheat times, which allows you to get back to heating the radiators more quickly. Trust me, I've installed a great number of systems just like this, I do know what I'm talking about

I am talking about using smart control and OT with a current system without changing out the hardware at considerable cost, to have a system that should, given the correct smart controls, be able to do what's needed. That being it can run the CH system at ~ 50deg for UFH and then raise the flow temp when the HW needs to be heated/reheated to 60deg for antibacterial purposes without any drop out of the CH.

This is all to reduce energy usage and costs, which is becoming a huge focus for my clients just now.

Can the boiler be range rated (like a combi) for CH duty because a say 10kw heating coil at 65C may now become a 15/18kw coil at 80C but if if 10kw CH range rating is required, for whatever reason, then a longer heat up time for the DHW.But you don't need a large capacity cylinder with PDHW, that's one of the joys of it. Also, if you set 60ºC flow temperature for heating the water it'll take forever. Wants to be around 80-85 for best reheat times, which allows you to get back to heating the radiators more quickly. Trust me, I've installed a great number of systems just like this, I do know what I'm talking about

Logic can do PDHW with WC or OT but it is a terrible boiler. Not only modulation is poor 6.1kw output and min pump speed is so fast that I have number of logics running on DT5 - which means that even with flow temp of 55 they hardly condense and are still much less efficient than they could be

Yes exactly same as VogueJust looking at UP website. It looks like the Logic Heat only boiler can also do this?

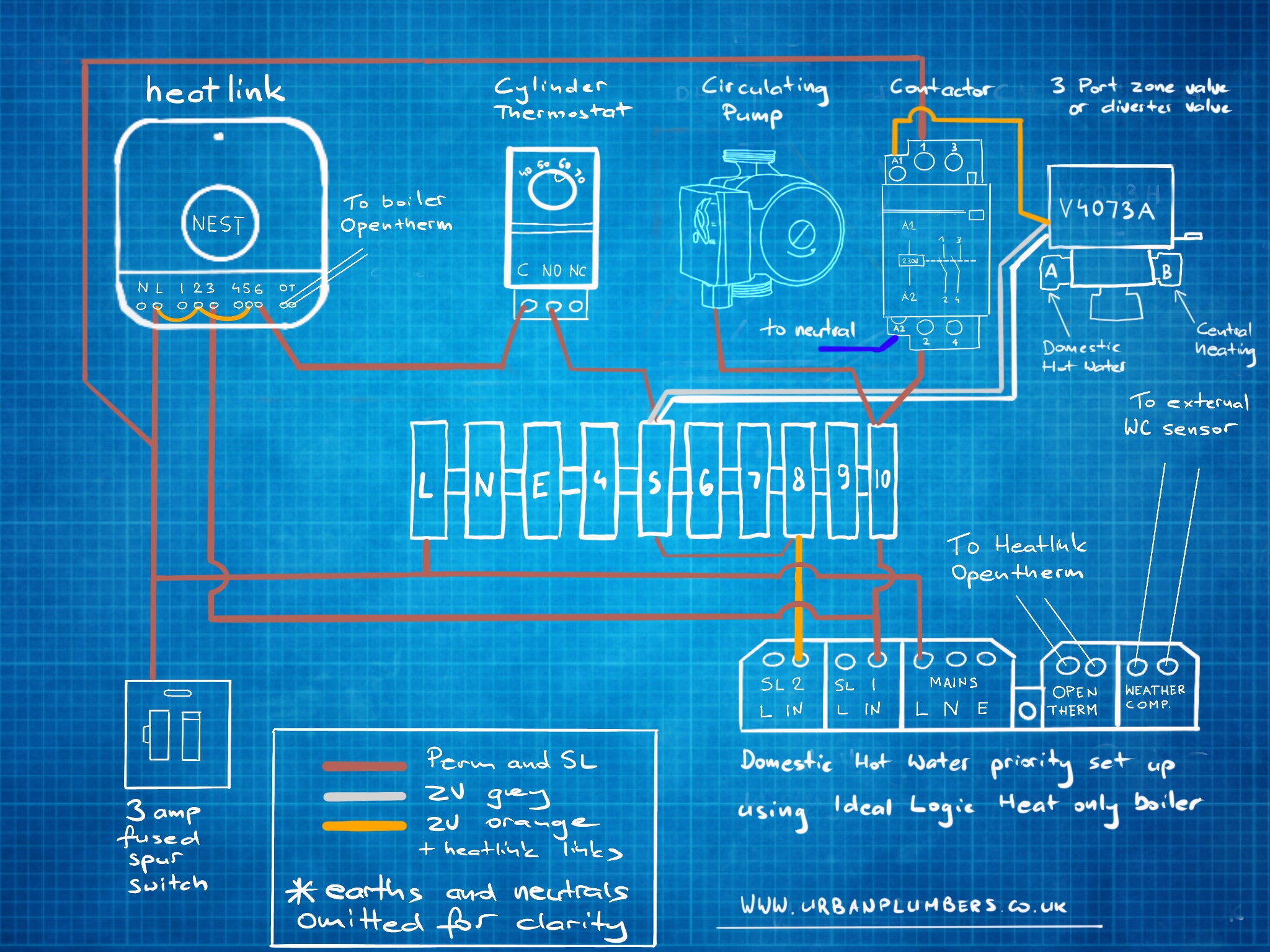

Ideal Logic Heat only boiler - PDHW wiring schematic - Urban plumbers

This is a wiring schematic for Ideal Logic H (Heat Only) boilers on Domestic Hot Water Priority set upwww.urbanplumbers.co.uk

Does it work exactly the same as the Vogue? I have S Plan+ which was covered in the video.

On Logic system boiler, I'd noticed the minimum pump speed is 70%, and thought that was very fast. Others go down to 10%. Why don't they let it go lower? Very strange. As Heat only boiler, then could use own pump. 24 KW goes down to 5.1 KW which is better than many but not as good as some. But I still think I would go for a better boiler with more control. Other quotes so far are for WB 8000 and Viessman 100-W.Logic can do PDHW with WC or OT but it is a terrible boiler. Not only modulation is poor 6.1kw output and min pump speed is so fast that I have number of logics running on DT5 - which means that even with flow temp of 55 they hardly condense and are still much less efficient than they could be

Wolseley also sell another Vokera system boiler called Evolve, but it's not on Vokera website.

The evolve was superceded by the Unica Max some time ago. Very similar but we changed from the aluminium exchanger in the evolve to stainless in the Unica. Very high spec of which you will possibly use 50%. I have put some videos on YouTube. Huge modulation on pump and you can set ∆T to a figure you want, there's a video on that.OT, WC etc but although it has the modbus smartkey socket any you buy at the moment will not have updated software.

I'll look it up. Wolseley website seems a bit out of date, showing Evolve and Vision non-PlusThe evolve was superceded by the Unica Max some time ago. Very similar but we changed from the aluminium exchanger in the evolve to stainless in the Unica. Very high spec of which you will possibly use 50%. I have put some videos on YouTube. Huge modulation on pump and you can set ∆T to a figure you want, there's a video on that.OT, WC etc but although it has the modbus smartkey socket any you buy at the moment will not have updated software.

It's all a bit confusing for me at the moment. I don't what they mean by "sanitary" or the "boiler card".This is from the Unica Max S I think but wonder how compatible this feature would be with standard or smart TRVs that keep increasing the dT as they throttle in?.,

Is this a continuously variable speed pump? As the TRVs throttle in, would it need to speed up to keep the same dT?

As delivered it runs self modulating at setting 85 which can be adjusted. It will operate anywhere in the graph shaded area. If you set a parameter between 10 and 20 then the pump changes to hold that ∆T.It's all a bit confusing for me at the moment. I don't what they mean by "sanitary" or the "boiler card".

Is this a continuously variable speed pump? As the TRVs throttle in, would it need to speed up to keep the same dT

If TRV's close the pump will slow down rather than speed up.

'Overpumping' is the cause of narrow ∆T's.

The software adjusts the pump speed dependant on parameter settings based on current draw in auto mode.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 0

- Views

- 457

- Replies

- 11

- Views

- 7K

- Replies

- 1

- Views

- 548

- Replies

- 4

- Views

- 5K

- Replies

- 0

- Views

- 2K