I have had to buy another mower & photos are attached.

A few little teething problems but nothing major & nearly completed.

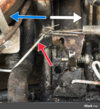

My question is I wish to bring the revs up a little.

Please advise what lever I need to bend or spring altered etc.

If I need to remove anything to show a different photo then please advise.

Thanks.

A few little teething problems but nothing major & nearly completed.

My question is I wish to bring the revs up a little.

Please advise what lever I need to bend or spring altered etc.

If I need to remove anything to show a different photo then please advise.

Thanks.