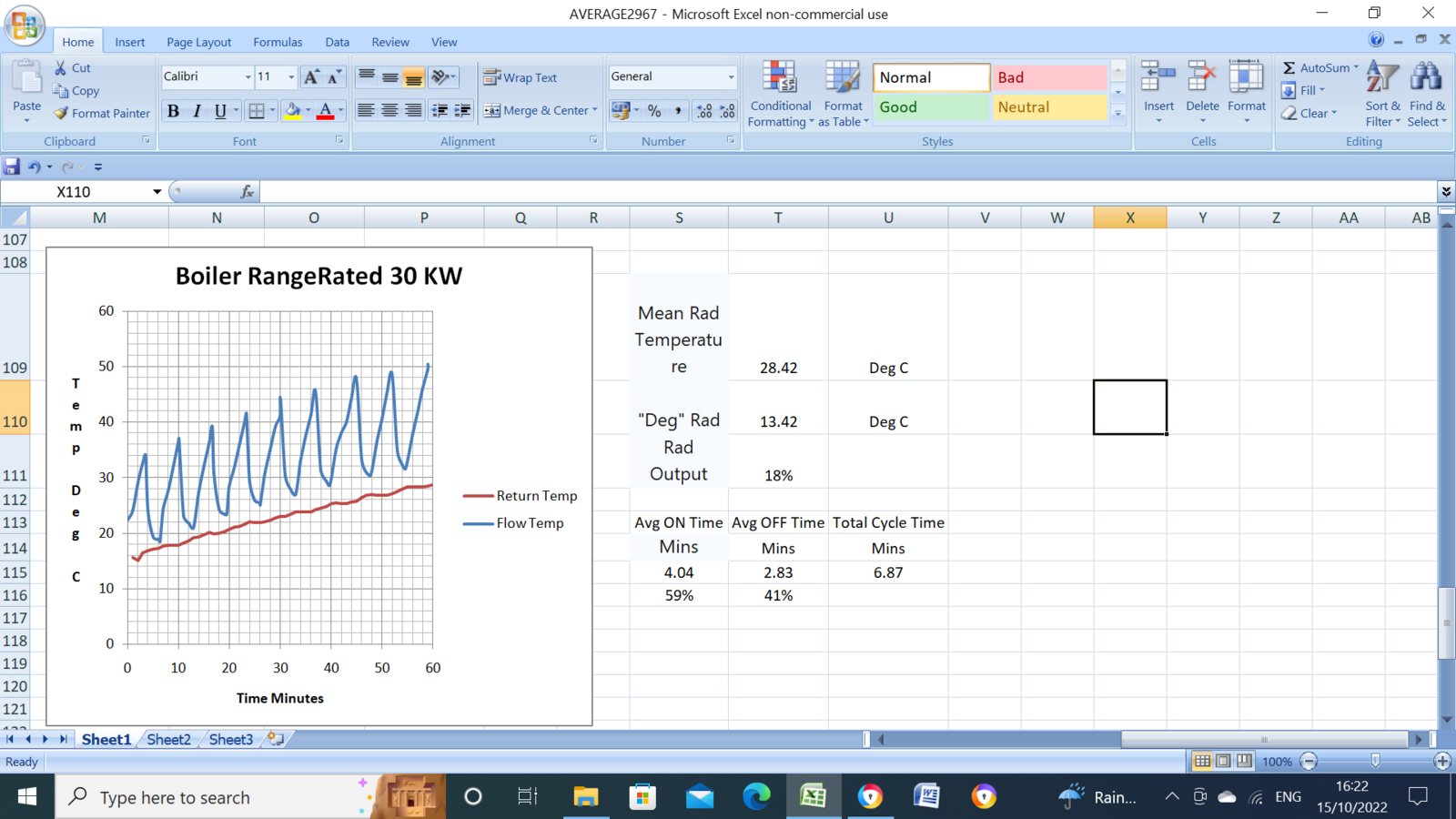

Here are a few numbers/trend etc from above.

The mean rad temp over that 60 minute period was 28.42C, assuming a room temp of 15C gives a rad output of 18% of max rated output, don't know how many rads on the system but assuming 25kw then the rads output was, 25X18%, 4.5kw so whatever way one looks at it, the boiler seems to have been producing very little power while cycling.

The mean rad temp over that 60 minute period was 28.42C, assuming a room temp of 15C gives a rad output of 18% of max rated output, don't know how many rads on the system but assuming 25kw then the rads output was, 25X18%, 4.5kw so whatever way one looks at it, the boiler seems to have been producing very little power while cycling.