It's a megaflo 250l. From memory, the stat is around 7pm which I believe indicates roughly 60 degrees. We only heat HW first thing in the morning, and then as and when required if necessary. So I was able to just override the programmer and it called for heat.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vaillant anti-cycle time question

- Thread starter fezster

- Start date

Sponsored Links

L8 would disagree.I find if unvented and you have a large enough cylinder then 50 c out at the taps is a good setting.

Does L8 make a provision for unvented water storage (plus 50c at the taps will be a bit hotter at the cylinder)? For OP so there had been some draw off in the day surprised that it cut out so quickly on return sensing, but was worth a go. Does it behave differently depending on d.0 as maybe you can find a sweet spot as we dont have access to what the actual logic is for the boiler either on the original PCB or the revised. From what I saw the revised still ramps up for 50 seconds but seems to allow a bit of an overshoot of flow temp. I also see from cold the boiler starting at less than 75% of max rated temp but from a hot start it still does the stupid 75% which is a bit daft.

I was kind of hoping this setting might have some effect on how quickly the boiler recovers from s53. Might try that tomorrow (easy to replicate opening a cold zone), but thinking LLH is my next step. The other reason being that the constant extreme temperature differentials at the heat exchanger surely can't be good for its life!

Sponsored Links

How much is it going to cost to have a LLH, maybe time to get a new boiler which is a bit more tolerant to what you are asking. Maybe fudge something with 3 port valves as another option with a timer like https://www.parkelect.co.uk/timer-r...Q_zbh-mAyVjSipazTrbjMuV4sSSg5r7BoCt5kQAvD_BwE

Max flow rate @ 20dt - 0.45 l/s.These guys will make you one.

Header velocity - 0.22 m/s (54mm LLH required).

How much is it going to cost to have a LLH, maybe time to get a new boiler which is a bit more tolerant to what you are asking. Maybe fudge something with 3 port valves as another option with a timer like https://www.parkelect.co.uk/timer-r...Q_zbh-mAyVjSipazTrbjMuV4sSSg5r7BoCt5kQAvD_BwE

Interesting - I was just discussing with my father earlier that if I could have a zone valve activating turn off the Switch Live to the boiler for 5-10s, and then reactivate the boiler, this would allow the return temp to stabilise before the boiler fires up again. I haven't had a chance to look at the link you sent properly, but I'd be intrigued if I could put together a relay like that on the cheap.

have had these problems on large systems with high power boilers. afraid it happens with most manufacturers. installation of a LLH will solve it for most situations.

It's actually comforting to hear that hopefully spending money on a LLH will actually solve the issue! Thanks.

Max flow rate @ 20dt - 0.45 l/s.

Header velocity - 0.22 m/s (54mm LLH required).

I was thinking the Spirocross AX100 or the Worcester Bosch Greenstar Low Loss Header. I will, of course, be letting the installer decide which to go for, but it'd be useful to know whether either of these meet the criteria you have given. The Worcester is attractive because of it's price. The Spirotech is rated at 0.55 l/s and all I can find on the Worcester is that it is suitable up to 70KW. How do either of these figures relate to velocity?

Found this formula:

Max flow rate 38KW @ 20dt - 0.45 l/s = 0.00045 m3/s

Header velocity - 0.22 m/s

Diameter of header (mm) = (SQRT((flow rate*1.28)/header velocity)) * 1000

Much of the literature I've read says the header velocity should be 0.5 m/s, rather than 0.22 m/s.

How important is the spacing between the header tappings?

Max flow rate 38KW @ 20dt - 0.45 l/s = 0.00045 m3/s

Header velocity - 0.22 m/s

Diameter of header (mm) = (SQRT((flow rate*1.28)/header velocity)) * 1000

Much of the literature I've read says the header velocity should be 0.5 m/s, rather than 0.22 m/s.

How important is the spacing between the header tappings?

Last edited:

Oh dear.

The timed relays are cheap and can work in various modes (including delay on if you get the correct one). I have used them for pump overun duties just mounted in a 1 gang pattress.

Last edited:

Worcester LLH fitted to a 438 28 rads on two zones and 210 unvented purrs like a kitten. Just fit it and forget the maths guys.

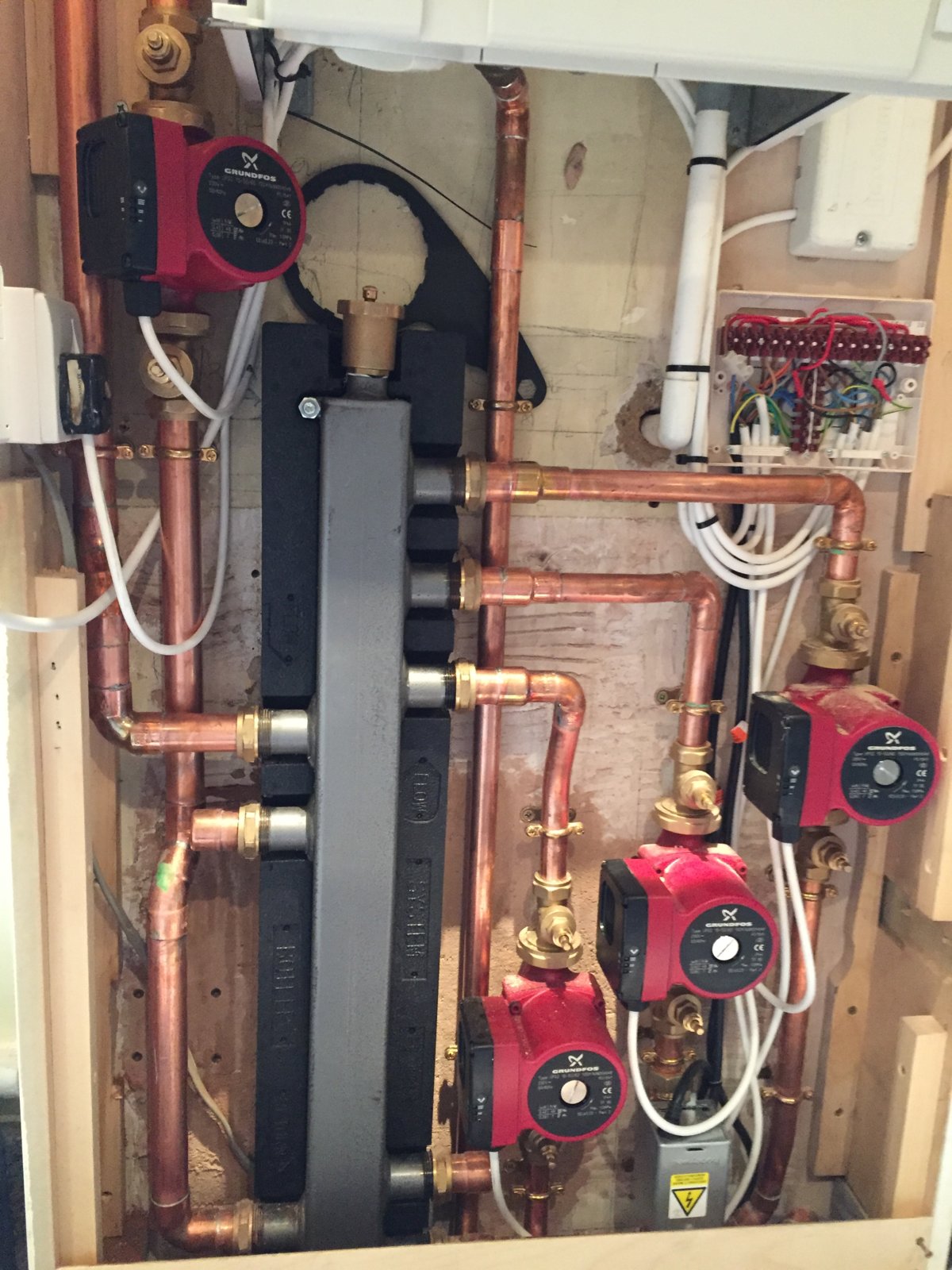

A picture paints a thousand words

Thanks. I wanted assurance the Worcester LLH could work with my Vaillant boiler. I saw no obvious reason why not, but good to know someone has done it. Hopefully my installer will be familiar with the combo too.

Thanks. I wanted assurance the Worcester LLH could work with my Vaillant boiler. I saw no obvious reason why not, but good to know someone has done it. Hopefully my installer will be familiar with the combo too.

Ask him to note the use of the two port valves. They act as a high temperature non return valves. The call from the zone powers the secondary pump and activates the valve. The orange is switch live as normal and the boiler controls the primary pump. Piece of cake, but there's a lot of materials and work there, so sit down when he gives you the price.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 1

- Views

- 7K

- Replies

- 31

- Views

- 944

- Replies

- 15

- Views

- 14K

- Replies

- 1

- Views

- 154