I'm actually toying with the idea of fitting another one in series so I can run the store even cooler.

Apologies to the OP for the thread diversion, but ...

IIRC it was on another forum where there was some discussion on how to optimise a heat bank setup. The context was probably how to a) maximise how much heat your could get out, and b) maximise the heat you could put in with things like thermal solar panels.

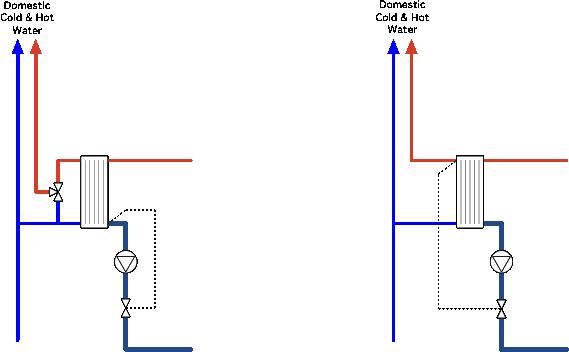

At first, there was a bit of a discussion around limiting the flow rate in the primary circuit, resulting in these two options :

The idea is to control the flow in the primary circuit so as to better match the DHW side. One directly controls the DHW temp, the other controls the tail end temp coming out of the PHE - if it's hot then you are putting more water through than is required. However, my (limited) experience with industrial systems says that controlling the output from a PHE by controlling the mass flow rate in the primary side is "challenging" to say the least - the conditions are so variable that it's not possible to setup (say) a PID controller to react quickly without being unstable under at least some of the operating range.

After a bit of thought, and a few iterations, I came up with this idea :

The theory is that the high flow rate round the primary of the upper PHE means you get rapid and stable response to changes in DHW load. The lower PHE ensures that by the time the primary flow goes back to the store, then it's about as cold as is practical for the given DHW flow rate. As I mentioned, the context was in maximising input for low grade sources (solar panels, heat pumps) - the lower the store temperature, the more heat you can get from a solar panel or the higher the efficiency of a heat pump. Even if these aren't applicable aims, it maximises heat extraction and it would certainly help in making your boiler condense !

While the TMV is shown with a remote sensor sensing DHW temp, if your PHEs are of sufficient capacity, then just controlling primary loop flow temp would probably give you good enough control.

I had a go at modelling it, but I couldn't find a model for a PHE that would work in a spreadsheet. I had a go at modelling one as a series of lumped heat exchange elements, but I couldn't get it stable.

I just throw this one your way since you were thinking of adding another PHE.