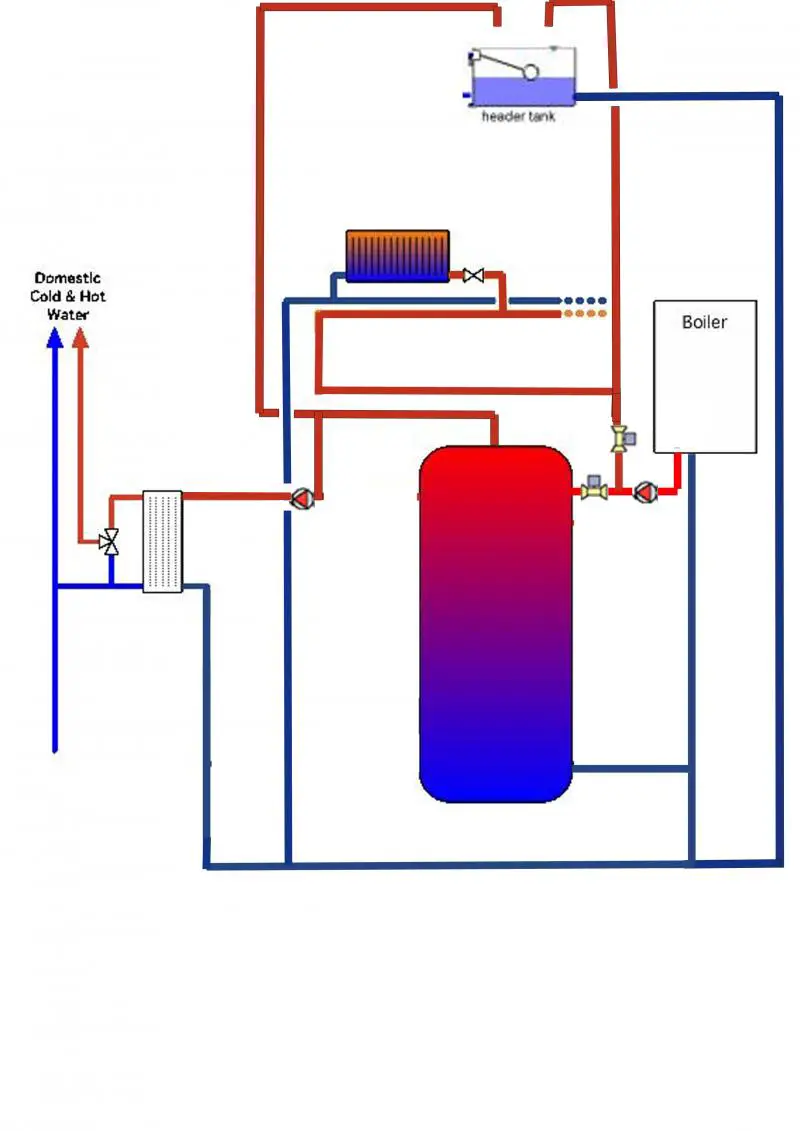

I'm going to heat the tank 'directly' (I'm going to cut 2 new flanges into it, making the coil redundant, and getting the full 24kw heating as opposed to just 4kw). Is there a way to make sure I won't run out of hot water as long as the boiler is replenishing the tank at the same time? Do I need to feed the tank from the boiler "top-down" i.e. flow at the top and return at the bottom then? At the moment, the full tank of water is used to fill the bath, so I don't want to end up with less hot water!

Would this work then? The return from the PHE doesn't go back to the bottom of the tank, but goes to the return on the boiler instead, so, when the boiler and its circulator pump is firing, the cold return from the PHE is 'sucked' through the boiler and back to the top of the tank, and no mixing occurs in the tank, and only when the boiler is off will the water return to the bottom of the tank and mix

In the general case, I'd say not. It would help when the store is well depleted and the demand is heavy - so the boiler is actually running full time, but in general the boiler tends not to hot at the same time as DHW drawoff.

You see, in general, you'll draw off hot water and the boiler won't fire immediately (or at all if the draw off is small enough). At some point, the tank stat will trip and the boiler will fire up - and is likely to keep running after the drawoff stops until the tank is hot enough for the stat to trip off.

In the "filling the bath" scenario - there will be considerably more flow through the cylinder than through the boiler - so it won't make all that much difference.

IMO, the question is really one of "how to ensure the boiler flow is always "sufficiently hot". In realistic terms, for the setup under discussion, I suspect it can be done just by carefully setting the flow rate - and I'd interlock the controls so the CH can't be on at the same time. So set a throttling valve so that under expected store bottom temperatures, the flow from the boiler is "sufficiently hot" to keep the bath filling at an adequate temp. This probably means "bending" the manufacturer's instructions slightly by running at a higher delta-T than they specify.

For example, generally guestimating some numbers. Suppose you decided that the minimum temperature you could cope with was 45˚, and you could throttle the flow such that the boiler had 30˚ delta-T at full power. That would mean that all the time the boiler return (from the store bottom) was above 15˚, the boiler could keep you going with 45˚ water. When the boiler return is above 15˚, the boiler flow will be hotter until it starts to range down to control at it's setpoint.

So you run the bath, initially you use the stored heat, then the boiler kicks in. If it's return is at 15˚ or above, it'll supply water at 45˚ or above. Initially I'd expect the return to be well above 15˚ so the boiler will range down to maintain (say) 60˚. As you consume the stored heat, everything will cool down (from the bottom up), and you should see a decline at the store bottom (and boiler return) temp drops. If the flows are fairly well matched, then the return from the PHE will be quite cool when running at full DHW flow rate.

Since you may be getting cooler water from the boiler than you have stored, you probably want to put the boiler flow into the store part way down - so when it's hot it will thermosyhon up to the top, but when it's cooler it'll fill up underneath the hotter water (or more likely mix with what'll still be hotter water). When you've consumed the hot water from above the boiler flow connection, you'll then get water at the boiler flow temp until you've largely depleted the store. You don't want the boiler flow too low down either - otherwise you'll find that you get a store full of a mix of the partly hot boiler flow and the fairly cool PHE return.

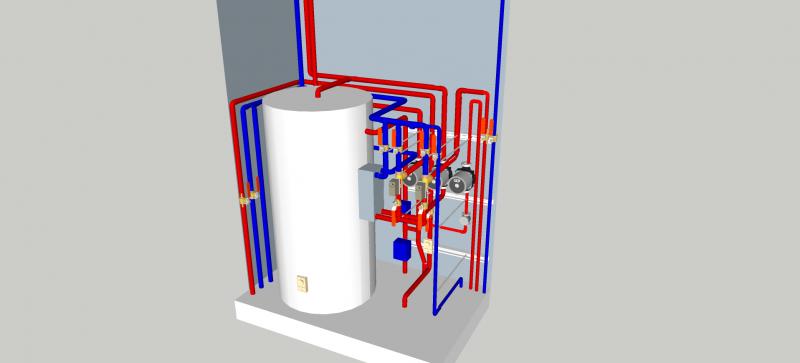

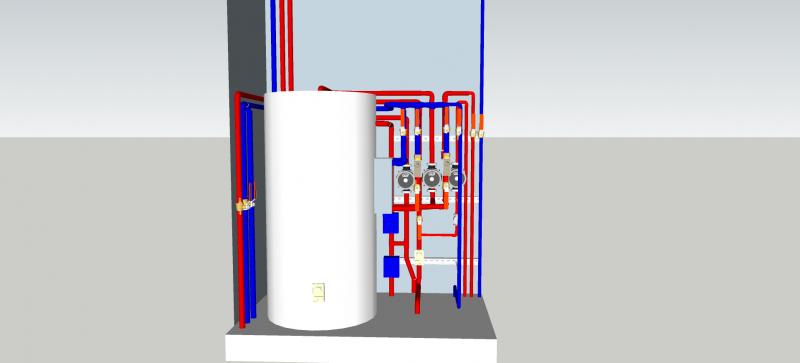

Try and picture (add arrows and numbers to a sketch if it helps) what flows you'll have, and what temperatures. Think about what this will do to the store, and how this will change over time. Perhaps I'm over analysing it - I suspect most just stick it in and work on having a "big enough store" plus "big enough boiler" to not worry about the details

Bear in mind that when drawing anything less than full DHW flow rate, you'll be putting warm water back in at the bottom of the store - the slower the flow, the warmer it'll be. It doesn't really matter in this case, but when trying to extract the most from (eg) solar panels, you try and get the bottom of the store as cold as possible so it'll accept the most heat from the panels on a middling day.

You also want to consider your boiler. If the return temp gets to about 54˚ or above, it'll stop condensing.

Also, would this pump be suitable to circulate water around the PHE?

http://www.ebay.co.uk/itm/Wilo-Dome...rials_Plumbing_MJ&hash=item2c7074814d[/QUOTE]

Don't see why not if you are having a fixed flow rate round the primary loop. Personally I'd be looking at a variable flow rate, with modulating pump and a thermostatic valve - but I don't know what valve I'd be using.

ok, thanks for all this advice, I hope you're getting something from it btw and I'm not just draining your knowledge base lol. The only reason I thought of returning the PHE to the boiler's return is so that WHEN the hot water valve is switched on (usually the case when taking baths), IF the tank stat temperature goes below say 55-60 degrees whilst running a bath, the cold return from the PHE will stop returning to the tank, cooling it further, and go straight back to the boiler for heating instead, that's my thinking. Otherwise, the boiler will be trying to heat all the cold water in the tank instead of just providing all the heat to the top of the tank and keeping my bath water hot. Catch my drift? Plus that would mean I only have to cut one new flange into the top of the tank, instead of 2