The installation instruction state :

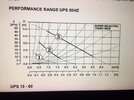

Available pump head at 20 °C system temperature rise 2.0

It's a Bosch Type UPS 15-60 HU1 3 speed pump

7 rads + towel rail , mid size 3 bed terraced house

I wouldn't even know where to start re curves, heads etc

Available pump head at 20 °C system temperature rise 2.0

It's a Bosch Type UPS 15-60 HU1 3 speed pump

7 rads + towel rail , mid size 3 bed terraced house

I wouldn't even know where to start re curves, heads etc