RCD or no RCD

- Thread starter DinoTheDino

- Start date

There is another option you might like to consider, and that's a key switch which cannot be operated accidentally. You would need to make up a combination key switch and fuse unit out of a grid range by combining parts such as the following:The reason for me asking is, the 45A has a switch that requires a good amount of force to switch on/off whereas the 13A can be switched on/off by the press of a finger. The location of the switch will be behind a cupboard, quite low, and i am afraid if someone is trying to access the (feeding) double socket next to it, might switch it off without realising it. Needless to say the adults in the house are going to be aware of it but you never know.....!

Links:

https://www.tlc-direct.co.uk/Products/MKK4917.html

https://www.tlc-direct.co.uk/Products/MKK4890.html

https://www.tlc-direct.co.uk/Products/MKK3702.html

https://www.tlc-direct.co.uk/Products/MKK3632.html

Plus a suitable back box, of course. That way you can use the key switch to isolate if the need should arise, but there's no chance of accidental switching off.

- Joined

- 12 Feb 2016

- Messages

- 26

- Reaction score

- 1

- Country

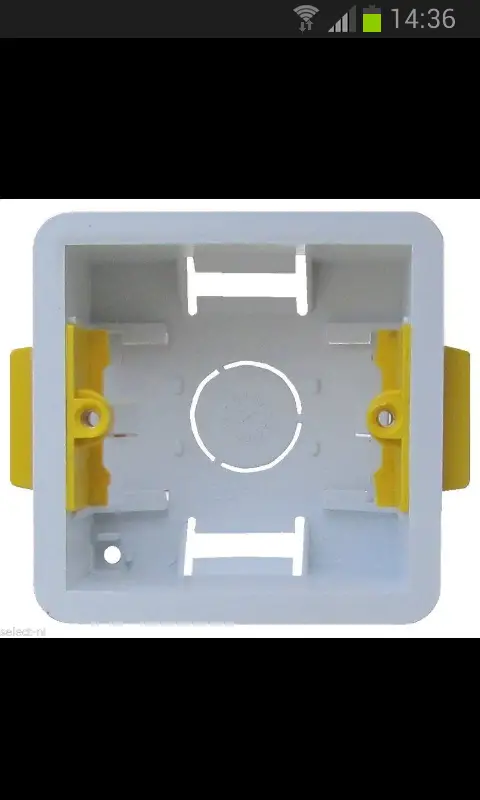

dry lining (plasterboard) flush wall box

My issue is the budget, which is quite limited. So I think I will stick with the A45 FCU option, the switch is really hard to operate! But I will indeed consider your advice, research research! Again!

But you could help me on another "problem", please!

How do I terminate the SWA, which comes through the outside wall into the living room, into a 47mm dry wall box (see image). I can't really see a way and this might change my plan again!!

The wall is: single plasterboard, insulation, brickwork.

I was planning to cut plasterboard, insert the 2 single 47mm back boxes to accommodate the unswitched 13Amp FCU and the 45A FCU and wire the SWA onto it !

I hope my question makes some sense and is easy to understand!

Regards Dino

P. S. Nice place you moved to, Redding, nice weather all year round!

Brilliant advice and I understand exactly what you mean PBC, that complies 100% with my needs, thank you!There is another option you might like to consider, and that's a key switch which cannot be operated accidentally.

My issue is the budget, which is quite limited. So I think I will stick with the A45 FCU option, the switch is really hard to operate! But I will indeed consider your advice, research research! Again!

But you could help me on another "problem", please!

How do I terminate the SWA, which comes through the outside wall into the living room, into a 47mm dry wall box (see image). I can't really see a way and this might change my plan again!!

The wall is: single plasterboard, insulation, brickwork.

I was planning to cut plasterboard, insert the 2 single 47mm back boxes to accommodate the unswitched 13Amp FCU and the 45A FCU and wire the SWA onto it !

I hope my question makes some sense and is easy to understand!

Regards Dino

P. S. Nice place you moved to, Redding, nice weather all year round!

Use a metal dual box rather than 2 single boxes and fit 2 plasterboard lugs. Fitting an armoured cable will still be fiddly if you aren't used to it.

I never liked those drywall/plasterboard boxes for anything, but there's just no way to terminate an SWA cable to one satisfactorily. The dual metal box that Freddo suggested would give you a proper way to terminate; note that we're not talking about a regular 2-gang box but a box which is effectively two single-gan in one, like this:

If that might involve too much cutting and patching of the wall, another option would be to mount a weatherproof junction box on the outside wall and run the SWA from that.

If that might involve too much cutting and patching of the wall, another option would be to mount a weatherproof junction box on the outside wall and run the SWA from that.

Hot in the height of summer, but the evenings then are just glorious. And after a rainy spell a week or two ago, it's sunny again and the forecast is for a high of 74 degrees this afternoon - Not bad for the middle of February!P. S. Nice place you moved to, Redding, nice weather all year round!

Terminate the SWA on the outside surface of the wall using a waterproof boxHow do I terminate the SWA, which comes through the outside wall into the living room, into a 47mm dry wall box (see image).

These are made for the purpose

Do not forget to order the earth clamping bar to make earthing the armour an easier job

You then wire from the external box through the wall using regular 2.5mm² T&E cable (I'm assuming you are using 2.5mm² SWA?)

- Joined

- 12 Feb 2016

- Messages

- 26

- Reaction score

- 1

- Country

Thank you freddo, option is registered and saved in my hard drive for further investigationUse a metal dual box rather than 2 single boxes and fit 2 plasterboard lugs. Fitting an armoured cable will still be fiddly if you aren't used to it.

PBC, you've made it againIf that might involve too much cutting and patching of the wall, another option would be to mount a weatherproof junction box on the outside wall and run the SWA from that.

I don't want to be labeled as pedantic

Terminate the SWA on the outside surface of the wall using a waterproof box

These are made for the purpose

Do not forget to order the earth clamping bar to make earthing the armour an easier job

You then wire from the external box through the wall using regular 2.5mm² T&E cable (I'm assuming you are using 2.5mm² SWA?)

Thank you too Taylor, on your suggestion though, I have to ask: why does the actual SWA, the steel protection, need to be earthed? Not that I disagree! Its just a curiosity question, considering that I use conductor 1=L, 2=N and 3=Earth.

I think by the end of this conversation I should roll on to the next college course to become an electrician; I should pass with ease thanks to you guys

PBC, this still bugs me, I've used every synapse in my brain to think of the missing bit I am missing, in regards to how to "enter" the junction box with the T&E in a weatherproof manner, I still can't seem to find it

Best

Dinothesoontobeasparkyhaha

- Joined

- 12 Feb 2016

- Messages

- 26

- Reaction score

- 1

- Country

.....I suppose i go for "external" glands, and again the question: where is the difference apart from the term external and internal? One is shorter than the other but ultimately they look the same, doing the same "job".

Taylor, I can see that the glands are supplied with "earth tags" the brass washers with the extra little hole, I assume for the earthing screw; so I understand your advise is correct. And the reason is???

Taylor, I can see that the glands are supplied with "earth tags" the brass washers with the extra little hole, I assume for the earthing screw; so I understand your advise is correct. And the reason is???

If the T&E comes out of the back of the box and goes straight through the wall, none of it will be 'exposed' - either to 'the elements' or to potential trauma.... my only "objection" would be: the little piece of T&E coming out of the wall and into the weatherproof junction box....., is it not a regulatory(?), but most importantly, a safety issue??? ...

For a start, many people use only 2-core SWA (for L & N), the armour being the only earth connection. However, the main point is that the armour has to be earthed for safety reasons - it is not there only to provide mechanical protection. By having it earthed, this more-or-less guarantees that if anything (e.g. a spade or other tool) pentrates the cable and comes into contact with the L conductor within, then this will cause some protective device (fuse, MCB, RCD etc.) to operate, thereby cutting off the power.I have to ask: why does the actual SWA, the steel protection, need to be earthed? Not that I disagree! Its just a curiosity question, considering that I use conductor 1=L, 2=N and 3=Earth.

If the armour were not earthed, then the worst-case scenario would arise if the penetrating object came into contact with armour and L (but not N). Nothing would trip/blow, the tool (if metal) would remain 'live' (with the person holding it probably standing on 'real' earth) and so would the entire length of armour be live

Kind Regards, John

The external ones are longer because they have an additional 'stage' to them. Internal ones have just one nut which grips onto the armour. External ones have an extra ('outer') 'stage' which seals around the outer covering of the cable, to 'prevent' water ingress......I suppose i go for "external" glands, and again the question: where is the difference apart from the term external and internal? One is shorter than the other but ultimately they look the same, doing the same "job"

Kind Regards, John

I haven't read all the rest of the post so it may not be possible.

Can you not run the swa cores through the wall?

Re: stuffing glands - see bottom of box link page.

Can you not run the swa cores through the wall?

Re: stuffing glands - see bottom of box link page.

He probably could. I hesitated to mention it because, although I would very happily do that (and advise people to do it) if the cores were going straight 'from box to box', or through conduit, the inner 'sheathing' (or whatever one calls it) does not seem very tough, and I might worry (if advising others!) a little about it being pushed through a 'jagged hole' in masonry. Having said that, if I were doing it for myself, rather than 'advising others', I'd probably just do itI haven't read all the rest of the post so it may not be possible. .... Can you not run the swa cores through the wall?

The other problem in this case is that, at the house end of the SWA, one would presumably have to also run a separate earth through the wall to earth the armour - unless one took the inner cores separately through the wall (without their 'sheathing') - which I would not think very advisable.

Kind Regards, John

Taylor, I can see that the glands are supplied with "earth tags" the brass washers with the extra little hole, I assume for the earthing screw; so I understand your advise is correct. And the reason is???

The earthing "banjo" washers supplied are general purpose items for earrhing the armour (using an SWA gland). These are fine for use in general boxes.

The WISKA boxes are a particular design and are not suited for use of the banjo washers.

The WISKA boxes, that I linked to, come all ready with threaded holes for you to screw the SWA gland into so saves you having to find a 20mm hole saw, extra nuts and bolts, it comes with a terminal block and is much easier for the DIYer (and many electricians) to use. In my opinion.

Thus video will show you how it all goes together, including use of the special earthing bar.. Also, note the external SWA glands, look out for the water-resistant seal nut that clamps round the cable and the longer rubber boot.

on YouTube there is also an excellent demonstration done by John Ward of how to terminate SWA cable.

This shows how the banjos can be used. You may need to use these at the shed end of the cable.

Last edited:

I'd run through conduit, but wouldn't consider doing it through "bare" wall. I don't think that inner layer of SWA is really designed or intended to be used as a protective sheath, as such.I hesitated to mention it because, although I would very happily do that (and advise people to do it) if the cores were going straight 'from box to box', or through conduit, the inner 'sheathing' (or whatever one calls it) does not seem very tough, and I might worry (if advising others!) a little about it being pushed through a 'jagged hole' in masonry.

Exactly my point. If you're talking about leaving the cores within that 'sheathing' then, as I said, one would also have to run a separate earth conductor (at least at the house end) in order to earth the armour of the SWA.I'd run through conduit, but wouldn't consider doing it through "bare" wall. I don't think that inner layer of SWA is really designed or intended to be used as a protective sheath, as such.

Kind Regards, John

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 20

- Views

- 4K

- Replies

- 11

- Views

- 3K