If the opening is 1600 and I am allowing - lets say - 6mm on each side, doesn't this reduce it to 1576 and hence, 788 each door? Want to be sure of the recommended gaps. Not trying to be pedantic!

I used 5mm for ease of figures - if I was quoting sizes in imperial then I'd used 1/4inch (which is slightly over 6mm). The difference is minimal in the first place And I know from experience that a degree of final adjustment is likely to be needed.

View attachment 353850

TO BE CLEAR - I am not proposing that I frame the doors as shown in this picture. Just pointing out the central lip/overlap, that I thought was a good idea.

Doesn't this run the risk that there will be a gap in the centre of these doors and someone will be able to see through. I thought the overlap/lip in the above will prevent this and also make it easier for me to cut the doors to size. It gives me some wiggle room.

That is what I'd thought. It's not the way I'd do that though. I'd use another facing board behind the face on one leaf.

My choice is on the first door on the opening side of the door the Ledges are modified, on the face side of the ledges are reduced by the thickness of the facing board - say the last 60mm. When you get to the fixing the last 2 boards a board (with either the Tonge or Grove trimmed off) should but put into the reduced thickness of the ledge), but you may wish to fix that board just after fixing the first board. Before you fix the last narrowed board plane the saw edge smooth by around the 2mm I'd previously commented on being oversize.

If you use the same material as the Ledge's then a 'Lap Having' joint is essential to provide strength.

That will make the door edge lighter. The width of the overlap board will cut size as part of the fixing in the door aperture work.

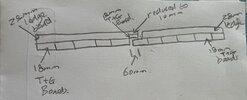

In my earlier sketch and following the advice from

@big-all, I have included a 6mm gap between the edge of the ledge and the T&G boards. I can make this 10mm if that is more appropriate.

View attachment 353851

I thought that if I set the gap between the door and frame to an appropriate distance e.g. 6-10mm, it will provide the space for expansion/contraction. Do you think it's still likely that I will need to take the door off after a year and adjust?

Never say adjustment will not be needed.

This is a new opening (two sets of double doors for two separate openings), as just about seen here:

View attachment 353852

It's got double studs for sides and the header of the door.

Your instructions here will determine where I fit the 3 horizontal braces shown in my sketch as I understand it. I can also see that you are suggesting that they are set in 7mm from the hinge edge. Again, just to make sure we are talking about the same section, I have proposed a 6mm inset in my sketch.

If you are happy with that - that's fine.

I was planning to use the 94 x 28 timbers for all braces. Let me know if you suggest otherwise.

When screwing the ledges into the T&G board, can I screw in the centre, from behind and should I insert two screws horizontally aligned? This will allow the boards to expand sideways.

I'd not screw in the centre of the boards as that means they could 'cup' away from the ledge.

Thanks for the tip on offset boards. I will look out for that!

I don't follow your instructions on nailing and is this necessary, if I put two screws into each board (through the back of the ledge, as suggested above)? Also, when pushing these boards together, should I not leave any gap for intra-board expansion?

Which is why I just push together this time of the year, in wet winter months I'd cramp up tight. If you are really concerned leave no more than a 1mm gap between each board.

Is this the diagonal braces shown in my sketch or should they be arranged differently? You can see how they relate to the hinge side and I think that this is what you are suggesting too.

You have the bracing spot-on for a door hinged on that side.

5mm is the final gap then. I may have misunderstood earlier.

Understood.

Is this the dome bolts or something else?

They are known as 'Coach Bolts' - 6mm diameter is appropriate.

The peril of reading down the passage! Screwing from the T&G board into the ledge presents a security risk as someone can unscrew and gain entry. I will screw from behind and follow your advice on the pilot hole. On screwing, is it advisable to insert two screws to each board and within 25mm of the right and left edge of each board? I was contemplating to screw each board in the centre twice (one screw above the other).

I'd not screw in the centre of the boards as that means they could 'cup' away from the ledge.