Also, the cable might not be spot-on 2.5mm² and, as it could cope with 54A at the centre, it isn't going to reach 70° in normal usage.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Confused over electrical cable length and size

- Thread starter Cavester

- Start date

- Status

- Not open for further replies.

Sponsored Links

Right, at last I think I am starting to understandYes but they are all around 0.004. Certainly a lot higher than 0.0017 (for 0.923 Ct)

Given the parameters that the book example indicates (13A in each leg {b}, tabulated CCC = 20A {It}, Ca-Cg=1, and max conductor temp 70° {tp}), the 0.923 figure for Ct is, indeed, correct in terms of Equation 6 in 6.1. of Appendix 4.

What we have been missing is that, whilst we have all been applying a correction factor for determining VD at tp (i.e. 70°), what Equation 6 is trying to do is estimate the required correction to VD for the actual temperature which will be reached with given values of Ib and It. For example, with everything else unchanged in the Example, if It were 27A (i.e. Method C), rather than 20A, then (per Equation 6) the estimated temp rise would be less, and hence the estimated Ct would be lower, hence VD (adjusted with that Ct) would be lower.

In concept, that makes good sense - why determine VD at 70° if a cable is so lightly loaded (in relation to its CCC) that the conductor temp is going to be far far less than 70° (i.e. if Ib<<It)? However, the equation is attempting to achieve that estimation of temp rise by including the term (Ib²/It²), and how well that really works I'm not sure. Given the apparent lack of 'precise science' in relation to the tabulated CCCs (i.e. It), with suspicions about the addition of 'safety margins' etc. (and, in the past, suggestions of changes for what might be called 'political' reasons!), I would definitely have my doubts.

The other odd thing about Equation 6 is that it is stated that it is 'only' applicable for ambient temps ≥30°. Whilst that migfh not be uncommon in Portugal (and particularly if one ignores the last few weeks), in the UK .... !!

Kind Regards, John

I don't understand why this equation is for ≥30°. It cannot also be correct for ambient temperatures higher than that, surely.

If it is correct for 30°, would it not work for any ambient temperature selected?

If so, why not just put the symbol Ca in the equation?

Anyway, the thread has been trying to work out the maximum ring length, so, as is usual, the worst case scenario has been used.

Presumably no one would want to install one considerably greater than 100m. even if that worst case is not applicable when installed.

Also, how does this come to 0.923 when they are using the usual 20 to 70°?

If it is correct for 30°, would it not work for any ambient temperature selected?

If so, why not just put the symbol Ca in the equation?

Anyway, the thread has been trying to work out the maximum ring length, so, as is usual, the worst case scenario has been used.

Presumably no one would want to install one considerably greater than 100m. even if that worst case is not applicable when installed.

Also, how does this come to 0.923 when they are using the usual 20 to 70°?

Quite so. I was going to go on to explain all the 'problems' I am having with that equation, and you highlight some of those there.I don't understand why this equation is for ≥30°. It cannot also be correct for ambient temperatures higher than that, surely. .... If it is correct for 30°, would it not work for any ambient temperature selected? ... If so, why not just put the symbol Ca in the equation?

For a start, for a UK-based set of regulations to present an equation which is said to only be applicable with ambient temps ≥30° is clearly daft - and they don't even suggest what one is meant to do if the ambient temp is <30°! If they were simply intending it as a 'worst case' (for which Ca=30° would be a reasonable figure for the UK), that would be fair enough (i.e. they were assuming that Ca was at least 30°, even if it wasn't), but that's not what they say.

Secondly, as you say, it makes no sense that that equation can give correct answers for any ambient temp (provided it is ≥30°), given that it contains no terms that relate to ambient temp.

The equation is written in terms of It (the tabulated CCC). If, instead of that, they had used Iz (the CCC of the cable, given all required 'adjustments' to It), that would make much more sense. For example 4D2A and 4D5 give CCCs for an ambient temp of 30° (again, maybe a 'worst case' Ca for UK?) and 'operating temp' of 70°, assuming no other rating factors have to be applied. However, one of those additional factors is ambient temp (Ca) as given in 4B1. So, for example, although It for, say, Method C 70° 2.5mm T+E is always 27A (and Iz is also 27A IF Ca=30°), if Ca=40°, the Iz (with no other rating factors) is only ~23.5A, and only ~19.2A if Ca=50°. So, if they had written their equation in terms of Iz, rather than It, it would make very much more logical sense!

With that equation, if Ib=It (i.e. cable is loaded to the full tabulated CCC) and Ca=Cg=Cs=Cd=1, then that equation will give Ct=1 when tp (maximum conductor temp) is 30°, with Ct falling below 1.0 as tp rises above 30. However, this makes no sense to me at all. The purpose of Ct is to multiply it by the tabulated mV/A/m figure. However, those tabulated mV/A/m already relate to a tp of 70°, so why on earth should one have to multiply them by something considerably less than 1.0 when tp IS70?!!

I really can make no sense of this at all - and the above comments are 'just for starters'.

Also, as I hinted at last night, nor do I really see how the equation can give particularly accurate indications of conductor temp (based on Ib²/I²t). Whilst, for a given resistance, it is undeniably true that the amount of heat generated wlll be proportional to I², how that relates to conductor temperature (which, in the equilibrium state, is related to the balance between the rate of heat production and heat loss) is a much more complicated, and 'circumstance-dependent' matter.

Not really. As I said, what you have been doing is calculating the VD at 70°, without any consideration of Ib and It (or Iz), so that will usually go beyond a 'worst case' ('in normal service' - i.e. when teh circuit is not being used beyond its design parameters). The implication of the tabulated CCCs is that a conductor carrying the indicated current will (with the installation method concerned) reach a temp of 70. If me assume Method C 2.5mm cable, the 'worst case' being considered in 'the Example' would be for a cable with a CCC of 27A to be carrying 13A - and that would clearly result in a ('worst case') conductor temperature of considerably less than 70°. Even if the entire 13A load were at the centre, each leg (with a CCC f 27A) would only be carrying 16A.Anyway, the thread has been trying to work out the maximum ring length, so, as is usual, the worst case scenario has been used.

I don't think that we need to consider situations which go beyond the 'worst case' of a circuit being loaded to its full design maximum - for a start, there would be no end to that but, in any event, OPDs are designed to curtail such situations before any harm comes to the cable, and I don't think one would be expected to calculate VD in a circuit which was loaded beyond its design current - again, there would be no end to that!

I don't understand what you mean by "the usual 20 to 70". Whilst tp (=70) comes into the equation, as above, ambient temp does not. In terms of the parameters which exist in their equation, the 0.923 figure is correct.Also, how does this come to 0.923 when they are using the usual 20 to 70°?

Kind Regards, John

Last edited:

Sponsored Links

Ah. I may have confused the 20 as 20° but I don't think that makes any difference to my question.

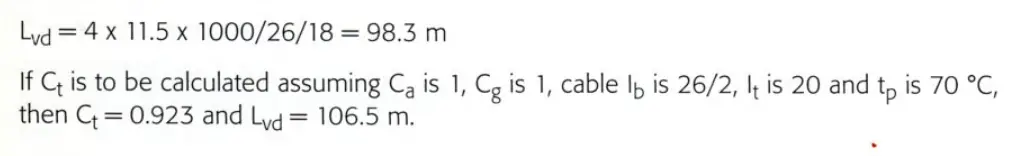

The top line is using 18 which relates to 70°, but then it says to calculate Ct and get 0.923, they also quote 70°.

Yes, the 20 is It - ie. they are talking about a 'just-compliant' ring final with a CCC of 20A.Ah. I may have confused the 20 as 20° ...

Yes, but as I have explained, although one has to put the maximum conductor temp, tp (=70°) into that equation, since Ib is less than It, it is trying to work out what conductor temp would actually be obtained - and, since that would be less than 70°, results in a calculated Ca less than 1, indicating that the VD would be less (with that Ib and It) than it would be if the cable were 'fully loaded' (Ib=It), and hence assumed to reach 70°.... but I don't think that makes any difference to my question. The top line is using 18 which relates to 70°, but then it says to calculate Ct and get 0.923, they also quote 70°.

If the cable were 'fully loaded' (Ib=It) then that equation gives Ct=1, which is what you would expect, since the conductor would (maybe - at least 'is deemed to'!) reach 70°, so the tabulated figure (for 70°) does not need any 'adjustment'.

Put another, perhaps simpler, way - the tabulated values of mV/A/m relate to a cable loaded to its maximum tabulated CCC, and achieving 70° as a result. With any load less than that maximum tabulated CCC, the temp will be lower, hence the mV/A/m less than the value tabulated (which assumes 'fully loaded', hence 70°).

Kind Regards, John

I perhaps should have added that, per my penultimate post, the way in which that is being 'realised' by Equation 6 seems all wrong to me.Put another, perhaps simpler, way - the tabulated values of mV/A/m relate to a cable loaded to its maximum tabulated CCC, and achieving 70° as a result. With any load less than that maximum tabulated CCC, the temp will be lower, hence the mV/A/m less than the value tabulated (which assumes 'fully loaded', hence 70°).

As always, perhaps I am missing something, but it seems to me that 'fully loaded' should relate to Iz and not the tabulated It - in other words, if there are factors such as grouping, ambient temp, short lengths of thermal insulation etc. which make the CCC of the cable (Iz) less than the tabulated CCC (It), then the equation ought to be using that Iz, rather than It - since I presume the assumption is that if a cable is loaded to its full Iz (which takes into account all of the various 'factors', and therefore may be appreciably lower than It), it is expected to reach a conductor temp of 70°, even though the current is less than It.

The equation, as written in terms of It, does not take any of those ('CCC reducing') 'factors' into account.

Kind Regards, John

Yes, not much point calculating that a 2.5mm² ring can be 106m (or 108.7) long for the actual loading if part of it later has to be increased to 4mm².

Indeed, but also, in the (I would imagine very common) situation in which CCC is 27A, rather than 20A, Ct then becomes 0.898 and (accepting what I believe to be potential shortcomings of the calculation) the maximum length thereby rises to 109.5 metres - conceivably of some interest to those re-wiring castlesYes, not much point calculating that a 2.5mm² ring can be 106m (or 108.7) long for the actual loading if part of it later has to be increased to 4mm².

Kind Regards, John

I haven't read the whole thread so I don't know if anyone else has picked this up.

Right - scribbling done. I actually make it about 104.3 metres. As I said, it's not a trivial calculation - so are you sitting comfortably .....

I will assume that the "12A evenly distributed along the two legs" is equivalent to 6A at the middle of each leg (i.e. a quarter of the total ring length from the CU).

Of that 6A, 4.5A will travel by the 'short route' and 1.5A by the 'long route'. The two 1.5A 'long route' currents (one from each side of the ring) travelling in the two 'middle quarters' of the ring will cancel, since they are going in opposite directions, and therefore will have no effect on VD.

Considering just 'one side' of the ring, the current in the half of that leg (i.e. quarter of the ring) more remote from the CU will just carry 10A (half of the 20A load at the centre of ring) (the two 1.5A 'long route' currents having cancelled). The current in the half of the leg closer to the CU will carry 14.5A (10A from central load, plus 4.5A of the 6A load on this leg, plus 1.5A of the 6A load on the other leg).

Yes, I actually "picked it up" myself, in post #44 ...I haven't read the whole thread so I don't know if anyone else has picked this up.

No-one has jumped on me yet, (despite the passage of best part of 24 hours), but I've just spotted the flaw myself!

There was clearly a fundamental flaw - since, with my calculations, whilst there was clearly a total of 32A worth of loads, there was only 29A coming out of the CU!

Whilst I still think I was correct in saying that the two 1.5A currents ('taking the long route') would 'cancel' in the two 'middle quarters' of the ring (so each just carried a net 10A - half of the central load), what I had overlooked was the fact that the same is not true in the two 'outer' quarters (the ones connected to the CU), since each of them carries the 1.5A 'long route' current from the other side of the ring. The current in those two 'outer quarters' is therefore (as I should have realised it had to be!) 10 + 4.5 + 1.5 = 16A - i.e. half of the 'central 20A load' plus 4.5A of the 'short route' 6A load on 'this' side plus 1.5A of the long route' 6A from the other side. My final expression therefore should have been ...

L = (11.5 x 4) / (26 x 0.018) = 98.3 metres

... which, of course, is exactly what 'the book' (and others) say (but I still don't know where BAS's 24A came from), and it is the temperature correction of that which takes it up to around 106 metres ('around', since it depends upon exactly which correction factor one chooses!).

Apologies for the confusion.

Kind Regards, John

Well done, simple mistake like that are so easy to miss when they cancel elsewhere.Yes, I actually "picked it up" myself, in post #44 ...

Kind Regards, John

I have now read through the thread and saw your corrected post but I have not tried to follow the myriad of calcs to any extent.

All seems to refer to the load being evenly distributed or at the centre point.

I'll put a spanner in the works now and assume all the load is at one point such that there is 27A in one leg and 5A in the other with a VD of 11V, so in very round terms (Head not calculator) 11/27=0.4Ω and 11/5=2Ω, total 2.4Ω. 2.4/0.015=160m. At the half way point this would give a maximum current of 11/1.2=9A or VD at 32A of 1.2x32=38V which is OK for a supply of 246V.

Where's that mansion beside a sub?

Quite - I am certainly as fallable as anyone else, probably more. It took me 24 hours to detect my 'flaw', which became obvious when I noticed that with my (erroneously calculated) figures, there was a total load of 32A but only 29A coming out of the CUWell done, simple mistake like that are so easy to miss when they cancel elsewhere.

Indeed. The former is, of course, the 'worst case', but it appears that the OSG accepts an assumption of 20A at the centre point and the remaining 12A evenly distributed.All seems to refer to the load being evenly distributed or at the centre point.

I'm not sure that's a 'spanner in the works' - you're simply moving away from the assumptions on which one should undertake the calculations. The closer the total load gets to one end of the ring, the longer could that ring be (VD-wise). As it approached the end of the ring (although cable would then be overloaded), the permissible ring length would approach infinity! What we have to do is design of the basis either of the worst case (all load at centre) or some reasonable assumption of likely use (such as the OSG's 20A at centre plus 12A evenly distributed).I'll put a spanner in the works now and assume all the load is at one point such that there is 27A in one leg and 5A in the other with a VD of 11V, so in very round terms (Head not calculator) 11/27=0.4Ω and 11/5=2Ω, total 2.4Ω. 2.4/0.015=160m.

Kind Regards, John

MOD Bet the Op's glad they asked now. This thread has been badly hijacked contrary to forum rules and is now closed, please start your own thread if you wish to continue the debate.

Last edited by a moderator:

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

- Status

- Not open for further replies.

Sponsored Links

Similar threads

- Replies

- 18

- Views

- 25K