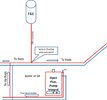

Open Vent (OV) is intrinsically safe as it runs @ atmospheric pressure and properly set up and looked after then it is perfectly fine, less stress oon components/fittings. Sealed allows the open vent, feed, cistern etc to be removed and can be a little more straightforward to install though safety devices are required - Expansion Vessel (EV) & Pressure Release Valve (PRV) plus a means to fill.

Sealed, I would suggest is easier to DIY than OV is as there is a bit of theory and technical specific setup needed to setup an OV system properly but as long as you follow the rules then it's either or.

Sealed, I would suggest is easier to DIY than OV is as there is a bit of theory and technical specific setup needed to setup an OV system properly but as long as you follow the rules then it's either or.

Last edited: