- Joined

- 27 Sep 2022

- Messages

- 298

- Reaction score

- 23

- Country

I can send a picture if you like, trust me it is without an expansion vessel, its a boiler from stoneage! It gets the job done of heating the house but with energy prices it is very in efficient.Boiler with pump but no exp vessel is a new one on me, but we live and learn!

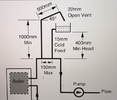

What is the advantage of having feed on return pipe, since I inted to install filter on return as well. Some posts I have read lately talk about having pump on return for heat only boiler, it gets very confusing. What's the best practice for feed and pump; flow or return?I would put the cold feed on the return pipe

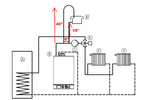

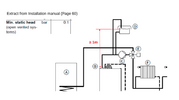

As Madrab said that I don't know what I have; sealed or OV as I thought of this system as OV so I bought a OV boiler (but PRV,NRV and no vent tell a different story). I think it would make sense to stick to OV and do the pipework and installation as per OV standard which is Vent,Feed, pump.If you use a separate vent

Can an OV boiler be used in a sealed system (by installing a exp vessel)?

The balcony where boiler will be installed is only 7 feet high so having min vent length of 40" from boiler + 24" boiler height would make me shift boiler just 1.5ft from floor. Are these lengths a must for hydronics and safety. Can these lengths be slightly less than this e.g why feed has a minimum distance of 15" from flow line?

Once CH is up and running and I get the required efficiency gains from boiler, I will definitely do it, Thanks for common return concept to boiler.if you're thinking of installing a HW cylinder in future