You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heat bank & boiler connections

- Thread starter muddyboots

- Start date

Sponsored Links

J

JonasX

You add the CH coil .

Space heating utilising a separate coil fitted to TS is NOT hydraulic separation.

It is as the water is both is very separate to each other. They do not mix.

I thought I needed to quote that statement before you started Googling for a clue about hydraulic separation, discovered how very, very wrong you are and edited it to make it appear that you aren't the clueless buffoon that we all know you to be.

Dan, others and myself have slaughtered you.

J

JonasX

The sludge in a SLUDGE BUCKET comes from the ferrous metals in the system, as a result of a high oxygen levels in the system, due to the quantity of water in the said system.

Cowboy, how can ferrous get into the thermal store when the radiator loop is separated by a coil in the cylinder? Now think hard about that. Take some pills first to stop the pain.

J

JonasX

Or even an open vented cylinder without a diffuser, a lovely collection of scale sitting in the bottom increasing surface area for the lovely Mr Legionella to bread. Sitting most probably in the mid 40's.

That is correct. The very bottom of cylinders do not get hot at all, no matter how hot it is at the top. It could be 85C at the top yet the bottom never gets above 40C.

Give me instant water heating any day.

Sponsored Links

J

JonasX

Well, as I have mentioned before, I have one, and have tried several methods of controlling the temperatures and monitoring stratification.

The thing is plastered with temperature gauges, and sensor pockets.

I have also had thing bad boy set up on it monitoring heat up, cool down cycles along with boiler F&R temps.

I can assure you I am not an armchair googler.

Dan, you obviously know your stuff on thermal storage. These plumber cowboys should take not. But sadly once a cowboy, always a cowboy, they will not change.

D

DeltaT2

The sludge in a SLUDGE BUCKET comes from the ferrous metals in the system, as a result of a high oxygen levels in the system, due to the quantity of water in the said system.

Cowboy, how can ferrous get into the thermal store when the radiator loop is separated by a coil in the cylinder? Now think hard about that. Take some pills first to stop the pain.

On most systems, the CH radiators are not on a separated coil, you tw.t. On most sludge buckets the radiators are heated by the Primary water in the said bucket. Perhaps on your expensively over-engineered sludge buckets they are on a coil. All these coils are a pointless expense, just still in an un-vented cylinder, much cheaper & it'll last for years.

These SLUDGE BUCKETS are useless!!

J

JonasX

The sludge in a SLUDGE BUCKET comes from the ferrous metals in the system, as a result of a high oxygen levels in the system, due to the quantity of water in the said system.

Cowboy, how can ferrous get into the thermal store when the radiator loop is separated by a coil in the cylinder? Now think hard about that. Take some pills first to stop the pain.

On most systems, the CH radiators are not on a separated coil,

Cowboy, when the CH is on a separate coil no sludge can occur. You have only come across poorly designed thermal stores and poorly designed system. Your primitive mind can't comprehend that quality designed thermal stores do not produce sludge.

Many knowledgeable and intelligent people have attempted to educated you, and others, on this topic - but to no avail.

Reading the posts on here it appears you are a crank who insults and they will not allow you on a forum.

a) A stainless steel cylinder with one CH coil is cheap to make. Like any other cylinder.

b) The boiler is connected directly.

c) A plate heat exchanger, pump, blending valve and few cylinder stats, c CH smart pump is all the extras needed.

It will be far more efficient and cheaper to run. The boiler will last and last.

Get to know all that. Then you can tell people in the pub. I'm sure you are in the pub all day and every day.

Dan, others and myself have slaughtered you.

Yes, Dan certainly has been slaughtered.

J

JonasX

Dan, others and myself have slaughtered you.

Yes, Dan certainly has been slaughtered.

You were comparing commercial standards of legionella prevention [L8] with instant domestic water heating - standards the makers of the 70% sold of market share in UK do not comply with. The commercial standards do not apply. You are very confused. You were slaughtered.

D

DeltaT2

SLUDGE BUCKETS are not installed in any other country in the world, they're expensive, sludge up, harbour legionella and fail in a very short time.

1000s have been removed in this area alone, developers & Housing Associations will not fit them, one major sludge bucket manufacturer has gone bust & more will follow. But the most important people that refuse to fit them is people like me, experienced Plumbers, we control the industry, we know best.

1000s have been removed in this area alone, developers & Housing Associations will not fit them, one major sludge bucket manufacturer has gone bust & more will follow. But the most important people that refuse to fit them is people like me, experienced Plumbers, we control the industry, we know best.

J

JonasX

This cowboy needs professional therapy. Legionella does not form in the instant waterways of thermal storage, no more than in any combi.

Thermal stores are big on the Continent. They have many makers selling them - now in the UK as well.

The engineers employed by your local council are poor engineers, and you are worse. They should have specified the layout of the store and the design. More incompetence.

They should have specified the layout of the store and the design. More incompetence.

Thermal stores are big on the Continent. They have many makers selling them - now in the UK as well.

The engineers employed by your local council are poor engineers, and you are worse.

J

JonasX

I read that TMV blending valves on the hot water on storage cylinders will be mandatory. They are to make sure the storage temperature is about 60C. Is that true? When are they to be introduced?

J

JonasX

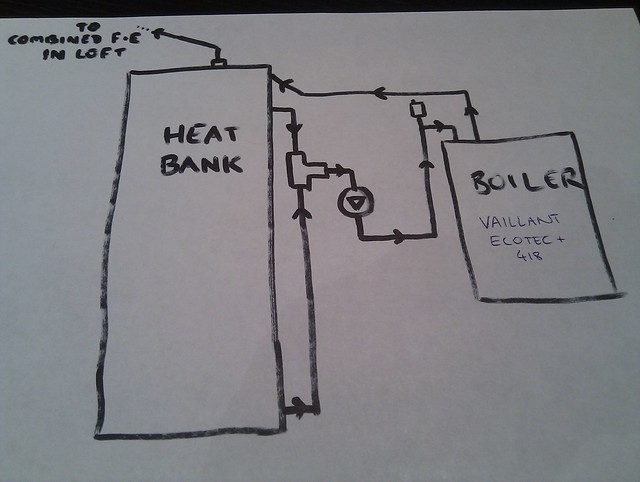

Hi all

I have a heatbank in our selfbuild, that is hooked up to a Vaillant boiler and has been working fine in the 3 or so years since it's been fitted.

It's all situated on the ground floor, with a feed and expansion tank up in the loft. Boiler is controlled by twin thermostats fitted low down in the heatbank. Boiler pump runs at the lowest of the 3 speeds, and the thermostatic valve in the boiler return is set as low as it can go. Return temps to the boiler start at approx 40deg when the stats fire the boiler, rising to around 50deg when they shut off again. Temp rise across the boiler is approx 25deg.

Here's a quick sketch of how it's currently setup:

(I've omitted the UFH & other connection gubbins for now)

Note that the pipe to the F&E in loft is also the vent (all 22mm pipe).

I've been intending to relocate the F&E tank, for various reasons, so it's directly above the heatbank rather than up in the loft.

I started reading the boiler manual to work out how best to connect the F&E tank, and vent.

I noticed in the boiler manual, and in most other diagrams online, that it seems more common for the pump to be situated in the flow from the boiler, downstream of the feed & vent pipes.

But on ours, the pump is in the boiler return. The thermostatic valve and pump were pre-fitted on the heatbank by DPS, our plumber just hooked it up to the boiler.

We've not had any problems running it though.

So my questions:

(1) Is it OK for the feed & vent to be taken from the top of the heatbank as per my diagram ?

(2) If not, and I were to relocate the feed & vent, where should it connect in to the boiler flow/return pipework in the above diagram ? And is it better to combine the F&V ?

(3) Could I run the vent straight out of the wall so it vents outside in case of a fault ?

(4) Is there any point in having the thermostatic valve in the boiler return ? It's set as low as it can go, I can't see any benefit compared to just running the boiler return directly from the bottom of the heatbank. Only time I can see it doing anything useful is during (very rare) startups from cold, so the boiler output is always at full temp (giving instant heat to the top of the heatbank and therefore hot tap water heat exchanger) even when the bottom of the heatbank is stone cold. In my mind the thermostatic valve is just a mass of brass radiating precious heat away!

Thanks for any thoughts or other observations !

Having a combined feed and expansion pipe off the top may cause the cylinder to implode if it boils over. Tee of the combined pipe at the top off the cylinder and take a pipe to the bottom of the cylinder. Have a non-return valve in this new pipe. This tops up the cylinder at the bottom but prevents circulation through pipes. When blowing off water gets back into the cylinder. Cheap and easy.

D

DeltaT2

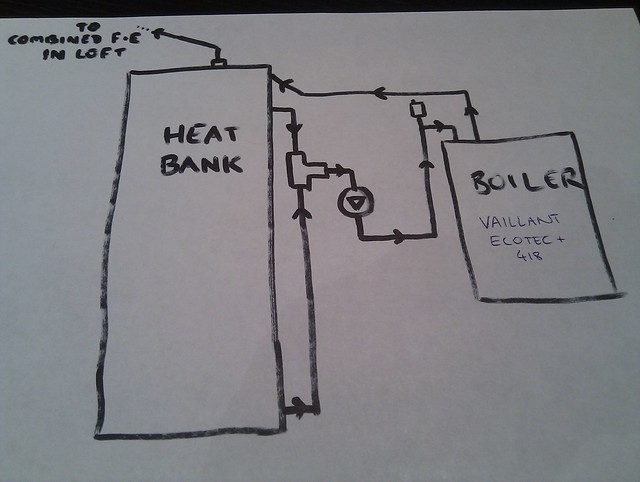

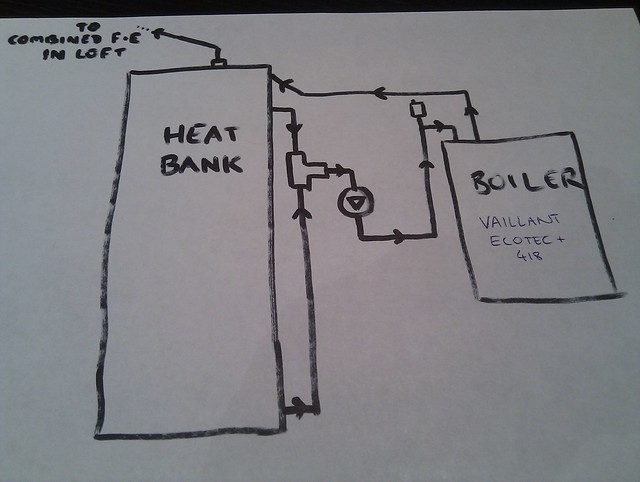

Hi all

I have a heatbank in our selfbuild, that is hooked up to a Vaillant boiler and has been working fine in the 3 or so years since it's been fitted.

It's all situated on the ground floor, with a feed and expansion tank up in the loft. Boiler is controlled by twin thermostats fitted low down in the heatbank. Boiler pump runs at the lowest of the 3 speeds, and the thermostatic valve in the boiler return is set as low as it can go. Return temps to the boiler start at approx 40deg when the stats fire the boiler, rising to around 50deg when they shut off again. Temp rise across the boiler is approx 25deg.

Here's a quick sketch of how it's currently setup:

(I've omitted the UFH & other connection gubbins for now)

Note that the pipe to the F&E in loft is also the vent (all 22mm pipe).

I've been intending to relocate the F&E tank, for various reasons, so it's directly above the heatbank rather than up in the loft.

I started reading the boiler manual to work out how best to connect the F&E tank, and vent.

I noticed in the boiler manual, and in most other diagrams online, that it seems more common for the pump to be situated in the flow from the boiler, downstream of the feed & vent pipes.

But on ours, the pump is in the boiler return. The thermostatic valve and pump were pre-fitted on the heatbank by DPS, our plumber just hooked it up to the boiler.

We've not had any problems running it though.

So my questions:

(1) Is it OK for the feed & vent to be taken from the top of the heatbank as per my diagram ?

(2) If not, and I were to relocate the feed & vent, where should it connect in to the boiler flow/return pipework in the above diagram ? And is it better to combine the F&V ?

(3) Could I run the vent straight out of the wall so it vents outside in case of a fault ?

(4) Is there any point in having the thermostatic valve in the boiler return ? It's set as low as it can go, I can't see any benefit compared to just running the boiler return directly from the bottom of the heatbank. Only time I can see it doing anything useful is during (very rare) startups from cold, so the boiler output is always at full temp (giving instant heat to the top of the heatbank and therefore hot tap water heat exchanger) even when the bottom of the heatbank is stone cold. In my mind the thermostatic valve is just a mass of brass radiating precious heat away!

Thanks for any thoughts or other observations !

Having a combined feed and expansion pipe off the top may cause the cylinder to implode if it boils over. Tee of the combined pipe at the top off the cylinder and take a pipe to the bottom of the cylinder. Have a non-return valve in this new pipe. This tops up the cylinder at the bottom but prevents circulation through pipes. When blowing off water gets back into the cylinder. Cheap and easy.

This is the most dangerous thing I've ever read on here, by far!! It also would not comply with the Water Byelaws. Please don't take this nutters advice.

J

JonasX

This cowboys thinks stopping a cylinder implosion will be dangerous. Who employs this sort. Only the unweary.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 54

- Views

- 7K

- Replies

- 2

- Views

- 722

- Replies

- 54

- Views

- 16K